A couple places up the street are for sale Jim, want me to refer you to an agent?

GRJ, thanks for the offer, but I am going to have to pass. I am following in your footsteps. I am just about 6 months behind you.

We bought a ranch townhome in late March. Rented it back to the previous owner for the month of April. We they moved out we cleaned it out and hired painters to paint all the rooms on the main level and the 1700 sgft finished basement. Finally closed the sale of our previous house on June 20th.

We are all moved in and currently the kitchen if being remodeled, new cabinets, sink, counter tops, dishwasher and lighting.

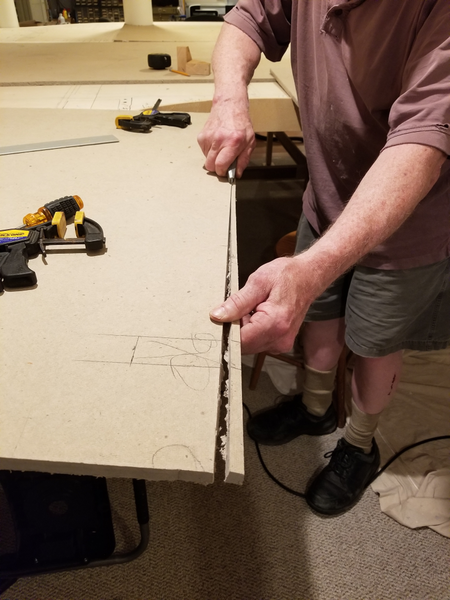

I am just a bit ahead of you with the layout build. Bench work completed, all track ( 2 main lines and a 7-track pass thru yard) laid, wired, debugged and fully ballest. Signals being installed, scenery about 5% completed. All structures are built and weathered. Access lift gate needs some fine tuning.

BTW, layout is HO, 22’ x 11’ being professionally built as per the track plan that was first submitted in June of last year. Final version of track plan submitted in November and construction started December 28 along with a 33% down payment.

Expected delivery late September / early October.

Long story short, moving again is out of the question.

PS - I have not posted anything about my layout because this forum is O Gauge.

![]()

![]()

![]()

![]()