That bridge is fantastic! I never thought to try a bridge. Will you paint it?

The sciatic nerve sure can be a pain. It would be nice if humans could get an update like our phones to address some faulty nerves haha

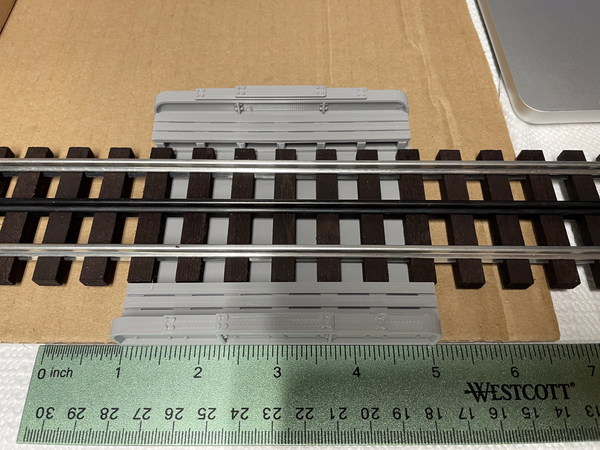

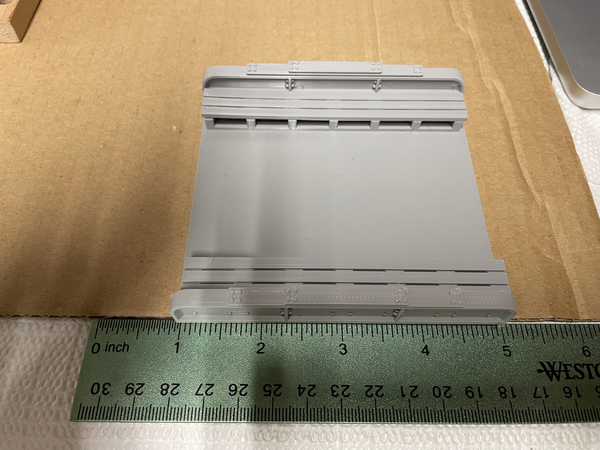

Yes it came out almost perfect, and it was from thingiverse for HO scale and my only contribution was to resize/scale it for O scale 1:48 I plan on painting it and weathering it also, which I have no experience doing, so if I mess it up then I'll print another one. It did take a little over seven hours to print. Of which I only checked up on it every 20 minutes or so while I worked on something else.

As for the sciatic nerve, I am getting relief from the steroids they prescribed and hopefully it will settle down again. It has been two years since I have been to chiropractor, hoping for another two this time around. With all new hips and knees I have run out of excuses to tell my wife why I can't do something. LOL

Thanks John

Thanks