That’s excellent John!

I took advantage of GRJs project as well. My two definitely do the job they were intended to do.

|

|

That’s excellent John!

I took advantage of GRJs project as well. My two definitely do the job they were intended to do.

@Tom Tee posted:John, you occasionally allude to the rest of the basement...Is there a print of the entire basement floor plan? Is there some way to penetrate a wall for a mainline run through so as to narrow the benchwork and open the aisle a bit.

Some folks run a line into and through the family room featuring full scenery which provides a very nice RR touch to an other wise same old same old family room.

Any time you can get 90 or 180 degrees of curvature out of the train room you can gain either increased real estate or aisle space.

Tom here is an overview of entire basement. One side is totally off limits for railroad.

Earlier in the thread you raised the question of controls. There is a third option other than either a fixed central control or full on TMCC or DCS remote and that is distributed control. In other words, you place the controls for switches and accessories near where they are located. Otherwise, you wind up walking around your layout following the train you’re iopersting, only to have to dash back across the room to throw a switch or operate an accessory. I’m exploring this for my new layout, which is similar in size to yours. Thanks to everyone who’s responding to your questions because they help me with my own thoughts.

Rubin

@RubinG posted:Earlier in the thread you raised the question of controls. There is a third option other than either a fixed central control or full on TMCC or DCS remote and that is distributed control. In other words, you place the controls for switches and accessories near where they are located. Otherwise, you wind up walking around your layout following the train you’re iopersting, only to have to dash back across the room to throw a switch or operate an accessory. I’m exploring this for my new layout, which is similar in size to yours. Thanks to everyone who’s responding to your questions because they help me with my own thoughts.

Rubin

Excellent point about having controls around the layout so you are in close proximity of the train you are running and the route you want to run it through. First priority is to get a system designed that will do both remote control from either a tablet or hand controller so you can be with the traain as you run it through its course. Then a main control center which is easy to accommodate, and then add controls around the layout if needed or desired. This is my first big layout so I have to depend on forum input or just adjust as go. Thanks for your valuable input and I will leave the design open to adding separate controls around layout. Again Thanks

John

I have all my switches and the turntable controls on the TMCC/Legacy remotes, I also have the Lionel LCS system on the iPad to control all the switches visually. I have siding power on individual switches placed around the fascia of the layout.

I plan on adding a manual turntable panel with a rotary switch and bridge controls in parallel with the command controls.

FWIW, I don't plan on any "master" control panel with everything on it. While they're impressive looking, I don't think they have the practicality of distributed controls.

@gunrunnerjohn posted:I have all my switches and the turntable controls on the TMCC/Legacy remotes, I also have the Lionel LCS system on the iPad to control all the switches visually. I have siding power on individual switches placed around the fascia of the layout.

I plan on adding a manual turntable panel with a rotary switch and bridge controls in parallel with the command controls.

FWIW, I don't plan on any "master" control panel with everything on it. While they're impressive looking, I don't think they have the practicality of distributed controls.

John,

Really nice set up, love the siding switches and your future plans.

My not knowing about today’s technology, makes it hard to decide on Lionel vs MTH although I have MTH tiu and AIU’s not sure if that was smart road. Of course right after my purchases, Mike head of mth announced retirement. 😒

you definitely have a flexible control situation designed. I hope I will learn more before it costs too much for the lessons, replacing is always cost inefficient to say the least

I started with all command controlled switches and the like, I figured that was pretty "universal" and I was sure I wanted that option. Now I'm looking to add some local switch control panels in a few strategic places. The good news is, some of the busiest intersections are right at the front of the layout with the yard entry, and the confluence of the mainline, sidings and turntable access loop. I can reach all those switches easily from the edge, so for manual control I just poke the button on the switch machine. My 10-track yard got all manual ground throws, I figured I'd already be at the yard anyway...

@gunrunnerjohn posted:I started with all command controlled switches and the like, I figured that was pretty "universal" and I was sure I wanted that option. Now I'm looking to add some local switch control panels in a few strategic places. The good news is, some of the busiest intersections are right at the front of the layout with the yard entry, and the confluence of the mainline, sidings and turntable access loop. I can reach all those switches easily from the edge, so for manual control I just poke the button on the switch machine. My 10-track yard got all manual ground throws, I figured I'd already be at the yard anyway...

Thanks John for your input, it is cherished as always! Seems like you planned ahead well and are able to adapt to your layouts usage. I am aiming at have similar flexibility with the turnouts and block power. Not sure if I need local block power for roundhouse tracks or if hand control will be easy to use. Some of my disadvantages stem from never using any controls except conventional. So running a train with an Ipad or remote device is not something I am at all familiar with using. So giving myself a ton of options as I go is mandatory. Ignorance is not bliss in this situation, and I have a lot of it. ![]()

Since my TT is out of reach, I have all command controls right now. I have the ingredients for a manual panel, a big rotary switch and lighted toggles, just haven't gotten to wiring that yet. That will be on the outside of the layout where operators will normally be running from. I strongly recommend having individual controls on each TT Whisker track, you don't want multiple engines waking up when not desired. ![]()

I did start with all command control from the remotes as I figured I could always add conventional after the fact if desired. Now that the track is down (at least all that's planned right now), I'm thinking on a few local control panels to make things easier. While it's nice to have command of everything, it's more convenient if you have a local control for some switches, quicker to access.

All my sidings have individual lighted switches so I can individually power them, and my four PH180 transformers that power the whole layout are on an RF remote so I can turn them on/off or reset them without actually physically accessing them.

Been working on electrical implementation this past week. Where I have concentrated my efforts was in the roundhouse track power control. I have an esp32 development board accepting input from either a push button switch or aiu channel. Then that has a wireless connection to a remote esp8266-12E development board controlling a relay board with eight relays to turn on and off power to the future eight roundhouse tracks. My intent is to use similar setups for overall block power control, turnout control, block occupancy detection and signal control. Tested transmission distance of over 40 feet. specs. I believe are 250' so it should be good when decking and other obstacles try to block the signal. These micro controllers are great for this purpose. Not much schematic to post as I am using development boards off the self and an ebay relay board with eight relays. Other areas may only need two or four relays, this will be designed on an as needed basis. My hope is to implement block power first and see how these all play nice with the total of 35 blocks to control. This may need to have its own topic so it can be easily found... thoughts anyone?

@gunrunnerjohn posted:Since my TT is out of reach, I have all command controls right now. I have the ingredients for a manual panel, a big rotary switch and lighted toggles, just haven't gotten to wiring that yet. That will be on the outside of the layout where operators will normally be running from. I strongly recommend having individual controls on each TT Whisker track, you don't want multiple engines waking up when not desired.

I did start with all command control from the remotes as I figured I could always add conventional after the fact if desired. Now that the track is down (at least all that's planned right now), I'm thinking on a few local control panels to make things easier. While it's nice to have command of everything, it's more convenient if you have a local control for some switches, quicker to access.

All my sidings have individual lighted switches so I can individually power them, and my four PH180 transformers that power the whole layout are on an RF remote so I can turn them on/off or reset them without actually physically accessing them.Thanks for the input

Hi John, Thanks for your input, it is always valued. I will take your strong recommendation on local control of the whisker tracks.

Interested in the PH180's are they built with RF remote capabilities? That seems like a great feature!

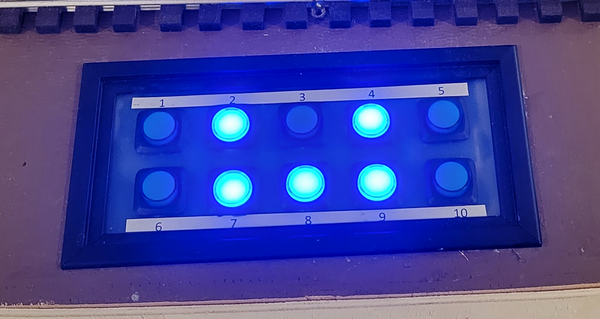

This is my main 10-track yard switch panel.

The Lionel PH180's are just a good transformer, no RF control. I use an off-the-shelf 120V RF remote system to control the whole layout and the individual transformers. This remote controls the four transformers, and the bottom control is the entire layout power. I have four of these laying around the layout, so I can grab one at any time. If I have guests, I typically put one in a pocket so I have instant access, "just in case". ![]()

The individual transformer receivers are controlled by these receivers.

And here's the master receiver for all the layout power.

@gunrunnerjohn posted:This is my main 10-track yard switch panel.

The Lionel PH180's are just a good transformer, no RF control. I use an off-the-shelf 120V RF remote system to control the whole layout and the individual transformers. This remote controls the four transformers, and the bottom control is the entire layout power. I have four of these laying around the layout, so I can grab one at any time. If I have guests, I typically put one in a pocket so I have instant access, "just in case".

The individual transformer receivers are controlled by these receivers.

And here's the master receiver for all the layout power.

Nice Setup for sure! Thanks for the remote info and idea! Also how did you mount the TIU etc. to the board you have so neatly populated with power and controls? Did you use velcro? Again THANKS!

Actually, the TIU is mounted using four screws, the holes in the corner go all the way through. The Legacy base has screw hangers, and so does the DCS WiFi module and the PowerHouse 180 transformers. The four DCS-RC boxes doing my Watchdogs are mounted with Velcro.

Thanks John for clearing that up for me. I was looking at the Dcs-remotes and did not see a mounting option. Again many thanks for the helpful information

next newbie question is: running power through the TIU (active mode?) or just putting TIU in parralell? Passive mode??

I run the TIU in active mode with power going through it. That gives the Remote emergency power off capability, and also I get a slightly better DCS signal level.

Passive mode is connecting the transformers directly to the track and connecting the TIU outputs directly to the track, no input power in the TIU inputs. However, unless you're SURE that FIXED #1 will ALWAYS have power, you need AUX power into the AUX Power jack.

GRJ, Thanks for letting me know what you use and prefer. I will do the same, now to incorporate the lionel controls. But I will take one thing at a time and get MTH setup first and tested.

On a side note to all, I am going in for replacement knee surgery tomorrow. I will be in hopsital for a very short time the rehab facility for about two weeks. So I will be out of touch and railroading will be halted. Thanks for everyone's help, advise and encouragement. It is very much appreciated.

Good luck with the surgery and rehab.

Good luck with the knee, I had minor knee surgery a few years back for a torn meniscus, probably not the same impact as a replacement! ![]()

Good luck and speedy recovery. I had one knee replacement in each of the last two years. If you do the rehab and exercises you’ll do fine. I’m back to walking 3 miles and bike riding 10+ ( I used to do 35 routinely. I can’t wait for Spring!). Before new knees,?stairs were tough. Now, no sweat. You’ll be glad you did it.

John, I’ll be praying for successful surgery and recuperation. Having both had one done, we know what to expect. I don’t know if that is good or bad.

Thanks to all for your well wishes and prayers. Knowing what to expect for me is worse than fat dumb and happy!

Good luck and our prayers are with you.

@Aegis21 posted:Thanks to all for your well wishes and prayers. Knowing what to expect for me is worse than fat dumb and happy!

I know, John! My wife dreaded her second one. After going through where PT was not able to break my scar tissue and having to have the manipulation and start all over, I hope my second one never needs done. We have to remember the struggle is worth it in the long run.

GRJ, what are those modules above your 180 bricks?

@Stephen G posted:GRJ, what are those modules above your 180 bricks?

Those are the MTH DCS-RC boxes. Each has one of my WatchDog Generator Boards installed to give continuous DCS watchdog signals on the track.

"On a side note to all, I am going in for replacement knee surgery tomorrow. I will be in hospital for a very short time the rehab facility for about two weeks. So I will be out of touch and railroading will be halted. Thanks for everyone's help, advise and encouragement. It is very much appreciated.

Starting work on RailRoad and loving it !"

Here's to a very good surgery and follow-up rehab!

Your knee will be great and any pain will diminish. Rehab is THE MOST IMPORTANT thing you can do! It can hurt at first, but that will change. My surgery cured a knee injury that occured when I was 20 (a long time ago!).

I had 12 sessions of PhysTherapy and I've continued with PhysTraining 2x or 3x per week for the past year. Best thing I've ever done. The trainer comes to our house, she brings the equipment, the backyard is our "gym" (we live in coastal CA so that's pretty much possible year 'round), and the work-outs are about 75 minutes. Hurt like h*ll in the beginning, but now it's just relatively pleasurable "work".

Good luck! That knee will be better!

Thanks again for all the prayers and well wishes. Operation was a success !!!

So all the prayers and wishes worked!

now for no complications and a vigorous physical therapy regimen.

Thanks To All !!!

Great news. Follow the PT and you will be up and around in no time.

Bob

Excellent news, John!

@Aegis21 posted:Thanks again for all the prayers and well wishes. Operation was a success !!!

That's great, you'll be back at it in no time! ![]()

John, glad to hear it went well. Just be attentive to any signs of inflammation. If any redness shows up take a photo so you can monitor the situation until you speak with the doctor. I read somewhere that working on a layout, and purchasing new items, will greatly help the PT process.

@Tranquil Hollow RR posted:John, glad to hear it went well. Just be attentive to any signs of inflammation. If any redness shows up take a photo so you can monitor the situation until you speak with the doctor. I read somewhere that working on a layout, and purchasing new items, will greatly help the PT process.

I read that as well, Jay!! I was negligent on that aspect of recovery, which is why PT had trouble with my knee early on. I was told it only happens to younger patients (I was 63) but later reading told me what those young guys who aren’t in the hobby didn’t know.

@gunrunnerjohn posted:This is my main 10-track yard switch panel.

Hi GRJ, nice panel where did you get those switches? Digikey?

thanks john

Those were lighted switches from some obscure mail-order outfit, I looked for an invoice but didn't find it. I have a bunch of them in my parts box, so I pulled them out to do the panel. Lots of similar switches available I think.

@gunrunnerjohn posted:Those were lighted switches from some obscure mail-order outfit, I looked for an invoice but didn't find it. I have a bunch of them in my parts box, so I pulled them out to do the panel. Lots of similar switches available I think.

Thanks John, I was just being lazy for sure and I have a feeling you use quality switches.

Hello All,

Well I made the plunge into 3d printing. So far it appears very promising on making detail pieces for the layout. It was a bit to set up, but really not too difficult once I got the overall scheme of things. And I cannot believe the deal that I got from Newark electronics. They had two of these units for sale Creality CR10-S pro for 173.44 each. Well time will tell if this was a cost effective purchase. However it is keepng me busy while I recuperate from knee surgery. I'll post a couple of pics as soon as I can. Don't know why the pics went to the top LOL I am pleasantly surprised on the detail, especially the luggage cart. I did tweak the settings to get a good print, however it is worth the effort!

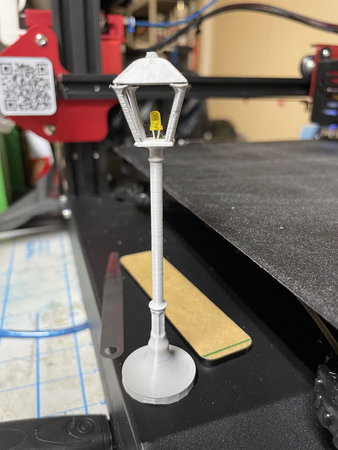

Hello All,

Here is my first attempt at a multi piece object. lamp post base, top and glass enclosure were printed separately to allow the led to be installed. I will have to tweak the settings for the glass enclosure for a better fit. The beauty of the software is you can take an object and scale it however you please. This is done in O scale 1/48 Here is a pic of the lamp post.

I have found that it's easier and faster to print parts you cannot find and connect them to parts you can find.

So I rarely print tubes I can find on Plastruct,

The base and head frame printed will have connecting tubes to fit the Plastruct tubes and holes for the LED(s)

Access to this requires an OGR Forum Supporting Membership