Besides a mess, my bench is home to curing ore loads. As I look for projects, I’m avoiding weathering at the moment, I decided to make new ore loads for my MTH ore jennies. Since I am running steam and early diesel power, the look of crude ore suits my fancy. In 1972, crude ore was still being shipped and sorted at the Proctor, MN yard. Train shipments were made up of various grades and colors of ore.

My goal is to create the same affect with my fleet of ore cars. I am using sifted gravel/sand gathered form the shores of Lake Superior. I cut base inserts from a 1” styrofoam, shaped it to fit my MTH jennies and added plaster to form a mound relief.

Painted/sealed the forms with latex paint. I coated the top surface with carpenters glue and then added a topping of stone and sand. Once I was satisfied with the look, I used the typical ballasting glue mixture to set the surface. When the weather warms, I will airbrush the loads to highlight the various shades of ore.

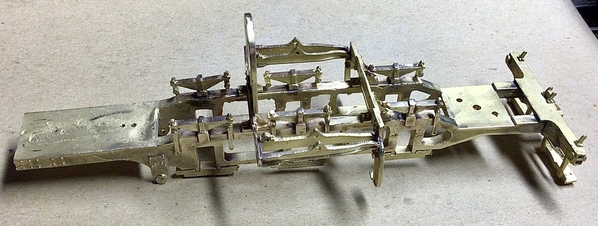

New and old:

The many mining areas in northern Minnesota produced a variety of ore grades. Trains would deliver cars to the Proctor yard where each car load would be graded. I had a good friend who’s summer job, while in school, was to climb up on jennies and collect ore samples for analysis. Iron content usually ranged from 32-48% with a mix of other compounds and moisture. In the early days, iron content ran as high as 68%. The job of the switch yard would be to sort the cars and build a train that met the analytical requirement desired by the steel company buying the shipment. A crew would then deliver this collection to the ore docks in Duluth or Two Harbors. Here the cars would be positioned over the dock pockets, some on the outside track and some on the inside track so that when the loads are dropped and mixed in the pockets they would contain the same uniform analytical ore mixture. Each pocket would be a mix of 5 cars and a typical shipment would require about 250 car loads. This sorting and arranging of cars was accomplished without the use of modern technology. A daunting organizational task that actually began way back at the mine.

Today it’s a far easier process with the advent of taconite pellets which are produced near the mines. To process taconite, the ore is ground into a fine powder, the magnetite is separated from the gangue by strong magnets, and the powdered iron concentrate is combined with a binder such as bentonite clay and limestone as a flux.

Taconite pellets have a uniform analytically consistency, can be stock piled, bulk loaded with conveyer belts and transported efficiently.

Dock at Two Harbors: Loading from the stockpile of taconite pellets. This ore boat has a self-unloading system which has moved out of the way during the loading of the rear hatches.

Note the absence of ore jennies on the dock. Taconite is loaded and unloaded using conveyer belts.

Heading soon to Two Harbors to dog sit! Have a good week!

Cheers, Dave