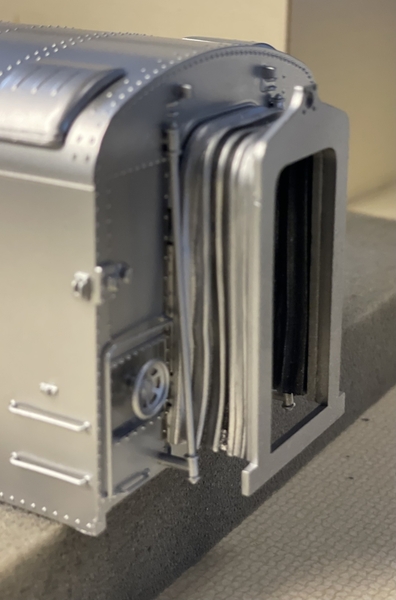

I normally wouldn't post the addition of a single detail to engine here but I wanted to add Lionel 8041-T13 water scoops to my fleet of NYC Hudsons and a sole Pacific I have. I had added one to a MTH Rail King Mohawk that I converted from ATSF to NYC and it was pretty straight forward and relatively easy, add some double sided Gorilla tape position between the tender trucks and apply some pressure. Slotted to get the scoops, a Lionel 785 Hudson, a MTH Rail King Commodore Vanderbilt, A MTH Rail King Empire State Express, a K-Line Dreyfuss 20th Century Limited and a K-Line 3010 4-6-2. I had forgotten about the locating tabs on the scoop so they had to be filed off and paint needed touchup. For one scoop no big deal, for 5, that's a lot of cleaning the file. So 5 scoops filed, painted, taped and ready to be applied. The 785 and the K-line Dreyfuss, no problems. The K-line 4-6-2 not so much. Being a much shorter tender and having openings for the air whistle the base of the water scoop was too long and would cover part of the whistle openings so one scoop would need surgery. So on to the two MTH Rail King models. The ESE installation was straight forward, however I'm so glad I did a test fit on each tender before applying the Gorilla tape. The trucks of the CV tender were hitting the base of the scoop limiting the turning radius of each truck. A second surgery candidate.

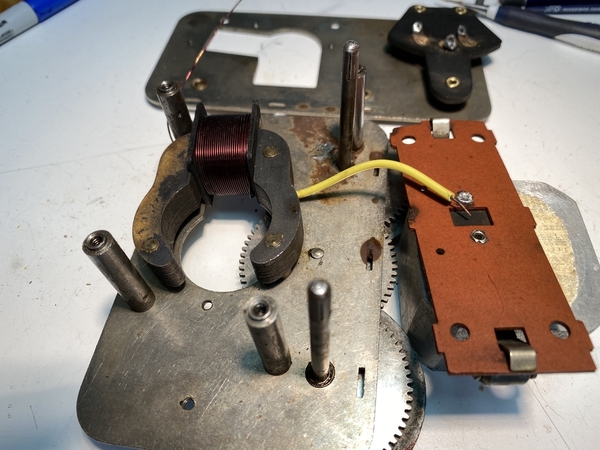

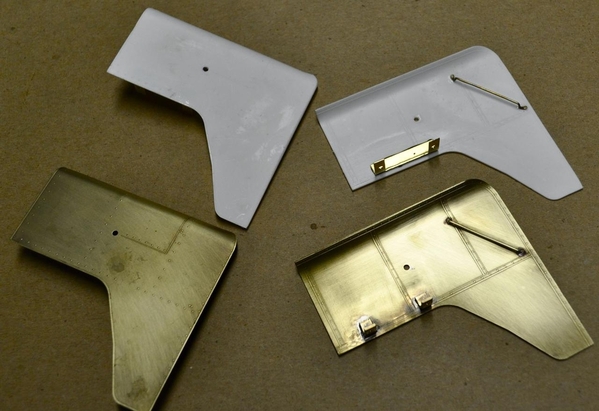

Out to the garage for Dremel work and magnification lamp because I didn't want to get into the scoop itself. The first one took several cut-off wheels because I snapped some re-entering my cut or changing the angle of attack. Smoothing and rounding edgers was done with a flat grinding bit. The second scoop must have been from a different batch made with a different alloy. Material would accumulate on cut-off wheels as if the alloy was melting, even when using a slower s speed resulting in changing cut-off wheels frequently. When the flat grinding wheel was used for final smoothing and rounding it was quickly clogged and final smoothing was done with a coarser cylindrical grinding wheel. Finally the last two scoops were ready for paint and application.

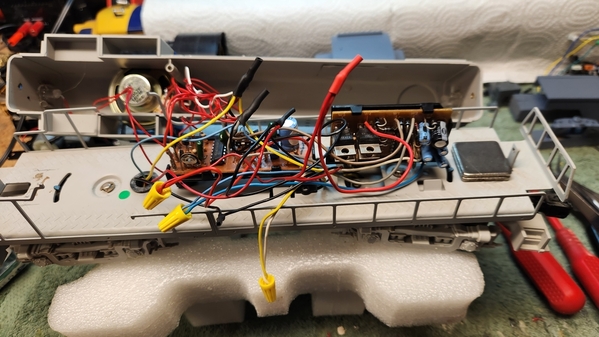

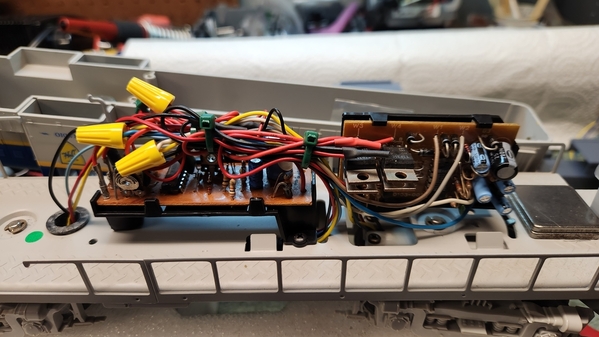

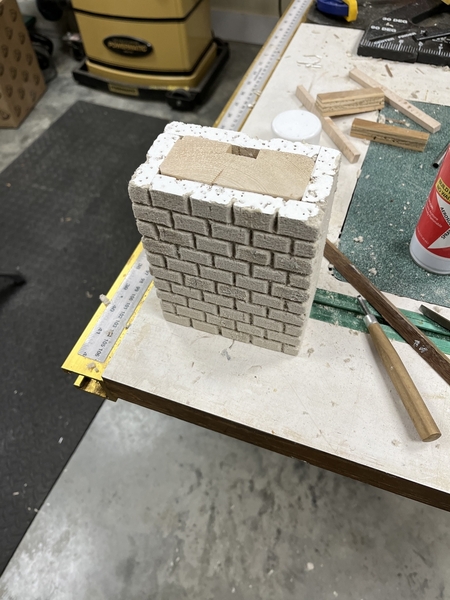

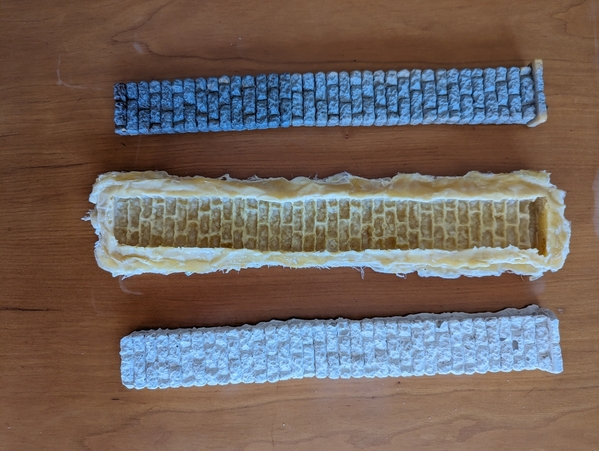

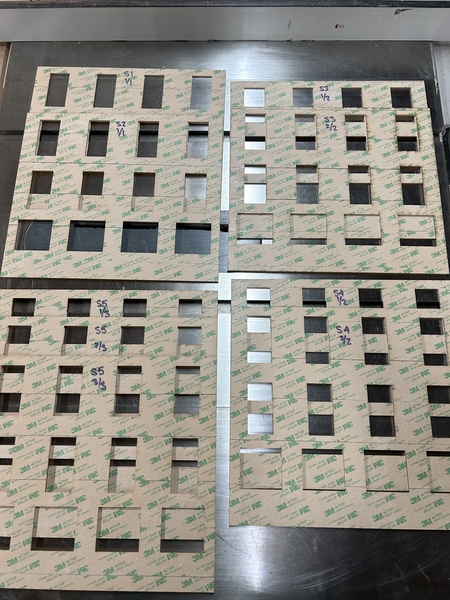

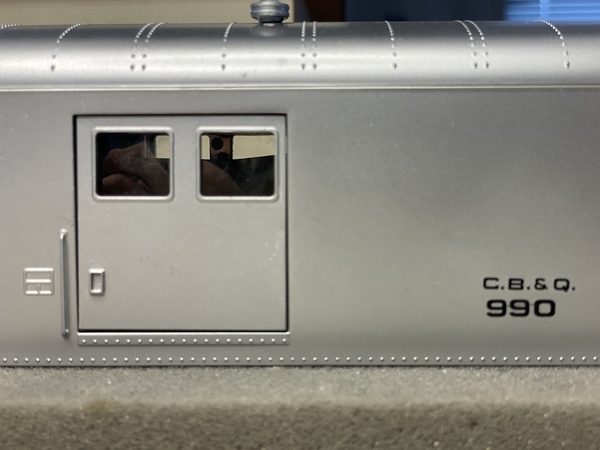

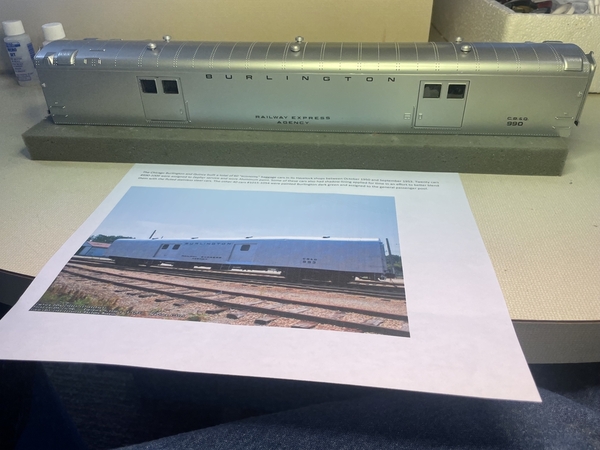

The as purchased water scoop attached to the K-Line Dreyfus and the shortened base needed for the Pacific.

You can see how much shorter the base had to be.

You can see how much shorter the base had to be.

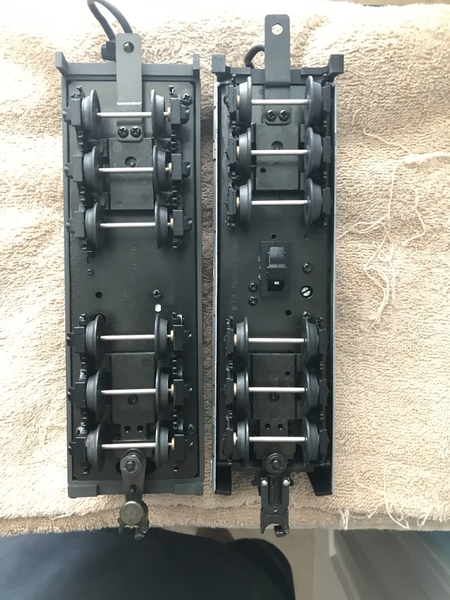

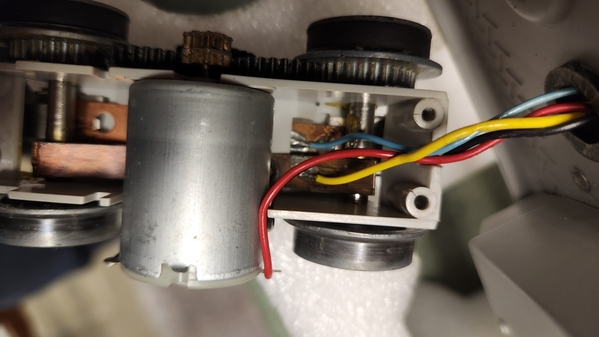

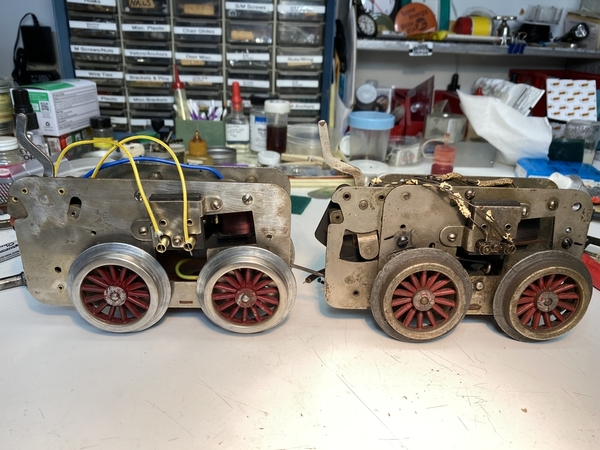

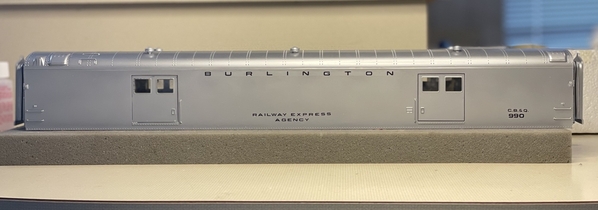

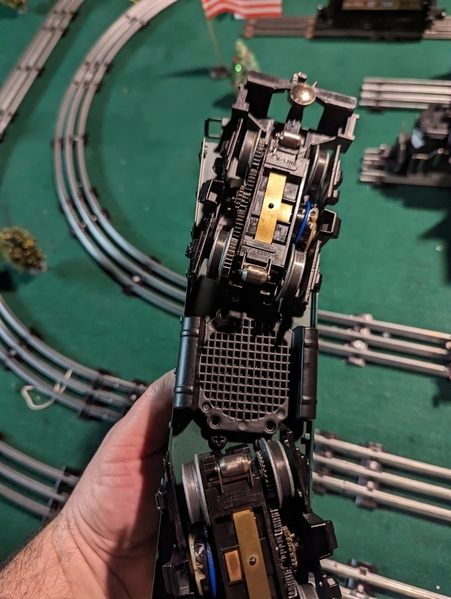

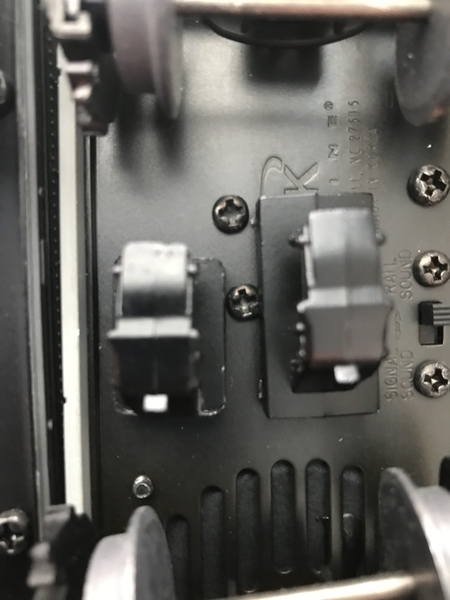

As can bee seen in the following pictures the two MTH Rail King Hudson tenders were dramatically different. The Commodore Vanderbilt tender appears more massive then the similar 6 axle Empire State Express tender it is 1/4" wider and it is taller. The trucks are longer than the ESE trucks, the side frames are thicker and the leading truck is set back further than the ESE's leading trucks decreasing the space between trucks for the water scoop. This differences would be understandable if these were from different mfrs but from the same manufacturer and the same trim line was totally unexpected.