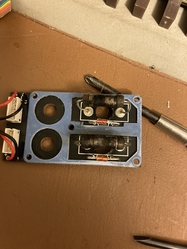

A customer who bought a 3759 less than 3 days ago came back in with it today and the whistle steam smoke unit fan was not working. The heater is still working (a little too well).

A customer who bought a 3759 less than 3 days ago came back in with it today and the whistle steam smoke unit fan was not working. The heater is still working (a little too well).

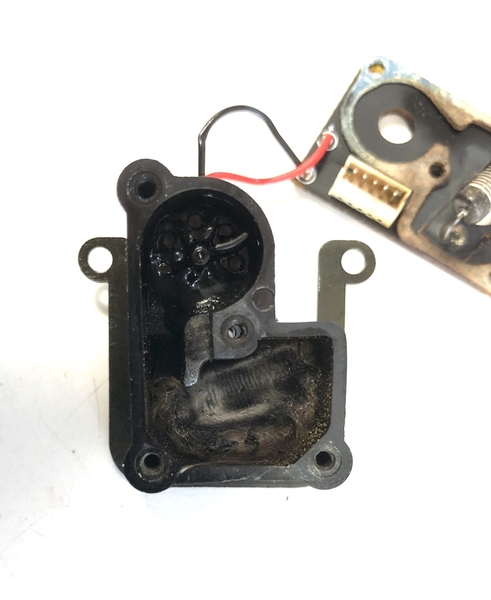

Opened it up and quickly saw why....

Heater got so hot it melted the fan and the wick, and funnel was ruined at the base.

Smoker was properly primed and he kept enough fluid in. Could it have been a board or software control issue? Told heater to run way hotter than it should have for too long?

Never seen one do this before. Awful.