Hello all, I just inherited a complete 1947 Lionel 2125WS train set with some extras. It has been in storage for around 70 years, and I am quite excited to start an adventure in model trains with it. I've attached a few photos of what I found when I unpacked it.

I'm a retired technical guy (50 years in the powersports industry) so I have some skills and engineering background.

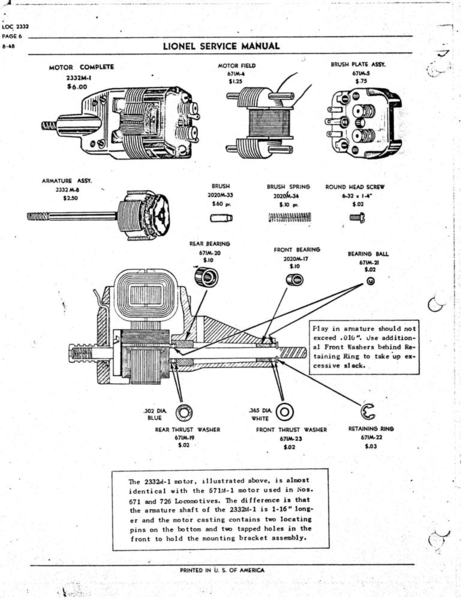

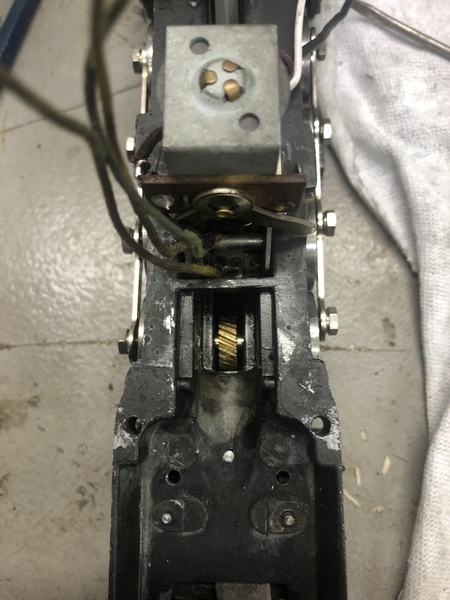

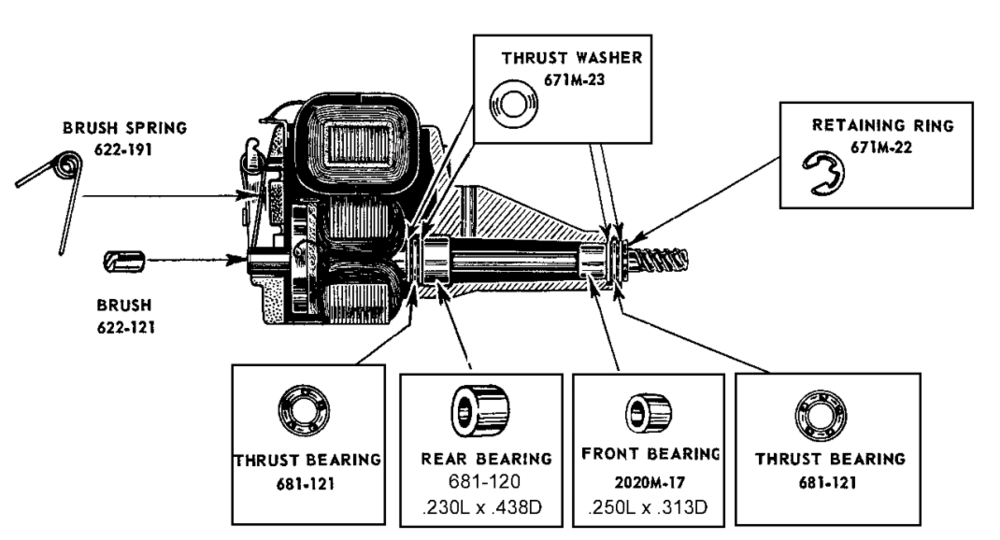

My conundrum is the locomotive lacks power and was a bit erratic. I have studied everything I could find and even bought Greenberg's manual. I have overhauled the motor (it was missing the upper thrust bearings and only had 5 balls in the lower). It spins freely and smoothly and runs up to speed when not engaged with the driven worm gear on the axle. I have replaced all the axle bushings and the driven worm gear, and the wheels turn easily by hand or when the chassis is pushed on the track. The E unit was cleaned and works properly.

But when I install the motor, following all the tips I have read, everything binds. Even if I loosen the motor to loosen the gear mesh the wheels won't turn and the motor is stalled when power is applied.

Can anyone here give me a suggestion on where to look?