Hey everyone I was wondering how safe it would be to run 270w of power on my loop instead of 180. I was considering using a TCP 400 & 2 180w powerhouses my main issue is fires, or damaging my trains. Looking for advice from yall. My layout used TMCC I like to run very long heavy consists. These consists will probably need 6 diesels which I’m struggling to do because I think I don’t have enough power. My layout is pretty temporary it’s on carpet & the wiring is not soldered to tracks mostly using crimp ons, electrical tape, wrapping the wire around the track part, or just taping the exposed wire in a way where it makes contact with it. I’ve ran a layout like this for about a year but I’m hesitant about doing 270w due to concern of fires or damage to trains. Also I saw a mention of track/wheel welding during derailments. Does anyone know if this is true? Looking for advice/tips on how to deal with this issue and if it’s even safe to due on my type of layout.

First off, I think you've jumbled a lot of inconsistent factors together, and need to be clear what *actually* fits together.

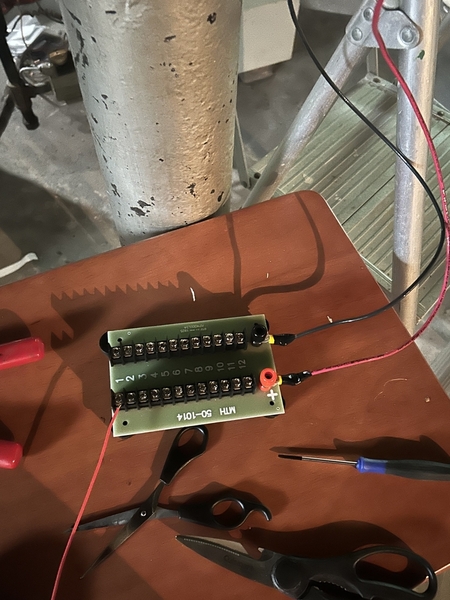

Transformer power ratings, such as 270 watt or 180 watt, are just a measure of the maximum rated power that can be drawn from the transformer before encountering overheating and/or circuit breaker problems. Regardless of the transformer rating, IMHO there should at minimum be an external and fast acting circuit breaker between any transformer and the track, both to protect the transformer and the source of the short or overload (you can literally melt the contacts off rolling stock or vaporize the wire to the track -- don't ask how I know!). Don't rely on the transformer's built-in circuit breaker -- it's designed *only* to protect the transformer, not your track, layout or rolling stock!

As others have already commented, secure electrical connections to the track, and between track sections, are absolutely necessary, both to provide reliable and consistent power to the consist *and* to avoid creating hot spots at the poor connections. IMHO 18 gauge wire should be adequate for most consists, especially if you provide multiple connections to the track, spaced at regular intervals, and I personally don't think switching to 12 gauge will provide any significant improvement, especially if some of your other electrical connections are less than secure.