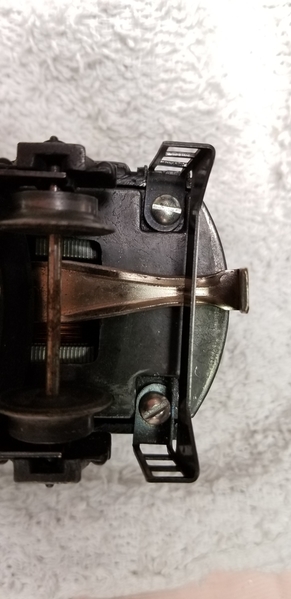

Yesterday I received a 671 Turbine (early smoke bulb model with the red "Atomic" motor) via an ebay purchase and as I am unwrapping it the metal steps that mount under the cab fell out of the box. In the sellers photos it is mounted so I can only assume it came off somehow either in shipping or when he was packing it so it may be innocent or it may be undisclosed damage. Looking at how this is mounted it appears to be spot welded as there are no holes in the step and just these 2 little stumps on the engine where it was mounted.

When I mentioned this to the seller I get this "oh that's not a big deal" yeah well its a big deal to ME because I didn't buy a repair job I bought what was supposed to be a SOUND engine. So before I blow my cork completely I'd like opinions as to whether or not this is a common problem and if there is a standard fix for this. It looks like it can possibly be drilled and tapped for screw mounting. I see these steps are available for sale so I assume this is not an uncommon problem.

Right now I am totally ****ed off just at his attitude alone. I sell thousands of dollars of vintage hi-fi equipment on ebay and if I treated my people like that I'd be out of business in a flash - besides it isn't right. BUT - perhaps I am over reacting for all I know this IS a common problem and it easily fixed. I want to bang this banana with negative feedback but I am holding back till I get some opinions on this. Guys like this make ebay a miserable experience. But again, maybe I am over reacting. The rest of the engine seems fine and the tender has a remarkably good sounding whistle. Those steps do look rather frail for such a massively heavy engine.