I should be getting Pennsy 520 soon as the Cumberland Valley sets have shipped. I'll also post my findings.

@Stinky1 posted:I should be getting Pennsy 520 soon as the Cumberland Valley sets have shipped. I'll also post my findings.

I wish they would have had that one as a stand alone as well as set offering, but alas, better this way I suppose.

I think Lionel knew the model of the sole preserved example would be the one most desirable (same case with the I1 Decapods) and sold them in the set intentionally.

All my buddies in the clubs haven't had any issues (at least yet) with their L1s, but we'll see how the 520 fares...

@WBC posted:I purchased the Santa Fe version of this locomotive. Other than the dry gearbox, there has been absolutely no problems with the locomotive. At $800 for a beautiful locomotive and brass tender, yes, I would buy again.

I think this was the better deal of the L1s' offered. More prototypically accurate compared to the PRR offerings with the incorrect tender. I thought the price was right on these models but was disappointed by the color right off the bat and then let down by the gearbox (and pickup roller) issues.

I do commend Lionel for making a back-drivable worm gear drivetrain. I think the first one I remember was in the CCII ESE Hudson and I think the general idea was to remove as much friction and backlash as possible for better closed-loop response. The Legacy era Canon powered ones seem decent with the universal coupling but these direct drive Mabuchi ones need some type of user adjustment. I wish they would build this modern era diecast stuff with drop-out axles and gears.

Treat yourself Dave you deserve it - you’re dead a long time - haven’t run my 1369 yet but it looks awesome 😊🚂

As I’ve mentioned before, I doubt seriously they went through the trouble to purposely design a back drive gear box. I believe ( and by no fault of Lionel ) that back drive is a by product of the work around needed for Legacy speed steps & the current crappy motor selections from vendor stock,….it just so happens that some steam locomotives they can get away with a tiny 385 and back drive to make it smooth………all the years of TMCC & ERR Cruise, and we never had nor needed back drive with a Pittman and a range of 16-18:1 gear ratios with locked gears……100 speed steps does just fine ……so other than Pittman’s exodus from our hobby, why all the bother for back drive? ….prove me wrong,….😉

Pat

@Norm Charbonneau posted:I do commend Lionel for making a back-drivable worm gear drivetrain. I think the first one I remember was in the CCII ESE Hudson and I think the general idea was to remove as much friction and backlash as possible for better closed-loop response.

I don't think they designed it to be back-drivable. I think it had a wimpy motor and they needed to spread the torque over a higher RPM range to be able to control it properly, and maybe just so that it could have any chance of starting a heavy train.

...these direct drive Mabuchi ones need some type of user adjustment.

That phrasing is being very generous.

Yeah I’m just going to disagree here.

@rplst8 posted:So the motor shaft needs a throwout bearing?

Seriously… I was considering a Pennsylvania M1 and maybe even an I1, but I’m really doubtful at this point.

There's a first gen Legacy m1b on the FS forum right now for about half of the new one.

I have one of these m1bs. Pittman can motor with the standard simple gearbox design that's still back drivable ( if that matters). It'll run just as slow and smooth as the new ones, maybe even better.

You won't have whistle steam , but you won't have a "disco lipstick" color on the tender either. ( as Norm aptly named it)

You also have idle and chuff sounds unique to this early legacy locomotive. Whereas today everything gets pretty much the same chuff, just a different whistle.

@RickO posted:There's a first gen Legacy m1b on the FS forum right now for about half of the new one.

I have one of these m1bs. Pittman can motor with the standard simple gearbox design that's still back drivable ( if that matters). It'll run just as slow and smooth as the new ones, maybe even better.

You won't have whistle steam , but you won't have a "disco lipstick" color on the tender either. ( as Norm aptly named it)

You also have idle and chuff sounds unique to this early legacy locomotive. Whereas today everything gets pretty much the same chuff, just a different whistle.

Thanks for the heads up. I already have an M1b, though the MTH version that lacks whistle steam. I was more interested in the as-built M1 with the exposed steam delivery pipes above the cylinders, slat or footboard pilot, and the forward positioned headlight. Also, the 2023 Vol. 2 release also has the short 110P75 tender available.

The other thing about that particular older Legacy M1b is that it has the dreaded first generation Legacy boards (R4LC and DCDS).

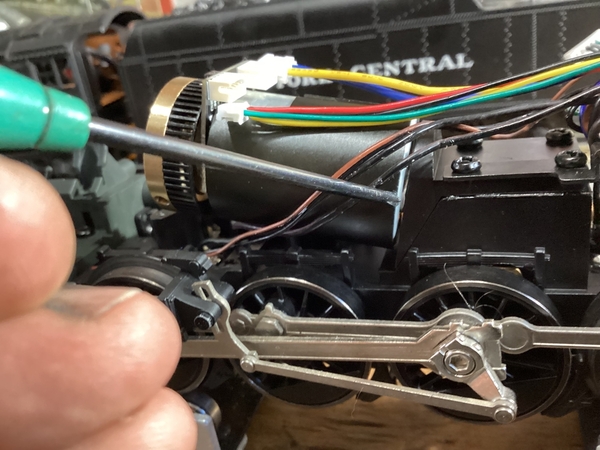

An update and final repair procedure for these engines. ( at least the latest ones I’m seeing ) …..Some of this credit has to go to Norm C. ….his assessment of the pitch depth is correct, ….So without reinventing the wheel, here’s an easier fix that solves the problem. Again, I’m on no, 2 today, and both responded perfectly to this treatment. As Norm pointed out, in reverse, the motor gear is actually pulled down into the gear box simply by the helix’s direction. When this occurs, the motor gear is beginning to ride up on the blind portion of the gear where it’s blank, and not prominently cut. This is what’s causing the skip & lock in reverse!….In forward, there’s not an issue, because the gear is now pushed back, and is riding on the worm wheel on the best cut of the motor gear ( perfect mesh ) …….So the quick painless fix, that’s non invasive, is to shim the motor back with thin spacers,…..I’ve pointed this out in the below picture where the screwdriver is pointing to,…..This example belongs to Alex W. so we’ll button her up, then Alex asked for some added details, and for fun, I’ll post up the before and after pics …..Also to note, the loose and missing screws on Lionel’s end has got to stop!….I know a screw here & there will work loose, but it is getting out of hand,…..missing fasteners, loose fasteners all over Alex’s example …..Beautiful locomotive , they just need to get their act together,…….

Attachments

Awesome! Thanks Pat!

Oh that's not good. Loose fasteners quickly make something good into something that ain't worth much. Especially if you hear dreaded sounds coming from what was your engine. No good. I do hope that the I1's have none of this crazy stuff, but alas, there will be something. Hopefully the tender is too long compared to the real deal, but you know that is the very least of what could possibly be wrong.

Thanks again Pat.

Here’s Alex W.’s ready to go to work,…..after fixing the gear box, we darkened all the side rods, and did a special touch to the crank pin fasteners, …..Alex & I both agreed the Lionel crew needed to be evicted in favor of the original fellas tasked to operate this appliance …..Alex commented he had the herky-jerky happening prominently in reverse,in a curve, so hopefully I can get this short video up here too,…..

Attachments

And a short video of reverse ….slow and smooth …..like I said, really need to also lay credit to Norm, as I utilized his thoughts in implementing a better fix ….So these L1’s can be made rock solid,…..

Pat

Attachments

Now can you make them not green?! ![]()

That's illogical, Bones...

Who made the crew figures?

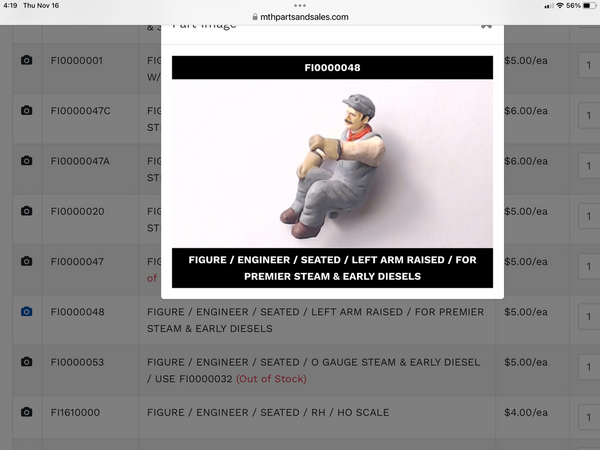

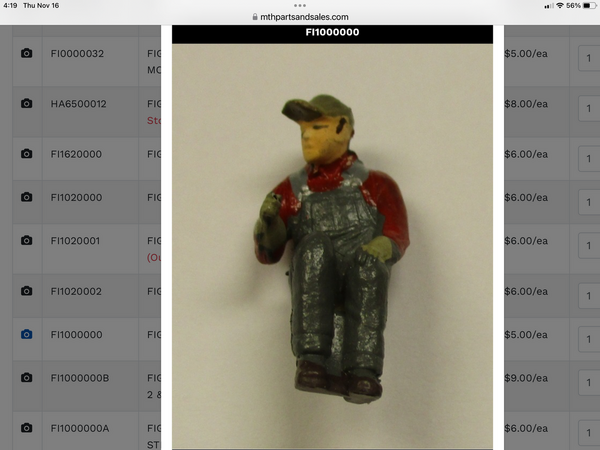

@Stinky1 posted:Who made the crew figures?

They are stock MTH figures from the later PS2 & all PS3 Premier & Railking steam….you can find them at mthpartsandsales.com ….heck of a value considering how detailed they are!….here’s a sample,….click on service parts, and search “figures’ loads come up,….