Probably wrong thread to ask, but l wonder if anybody, 3rd Rail?, has done an accurate, not a relettered Belpaire boilered version, three rail UP Consolidation or Mikado that would have run in NE Colorado collecting sugar beet cars? Any small UP freight steam ever been offered?

@colorado hirailer posted:Probably wrong thread to ask, but l wonder if anybody, 3rd Rail?, has done an accurate, not a relettered Belpaire boilered version, three rail UP Consolidation or Mikado that would have run in NE Colorado collecting sugar beet cars? Any small UP freight steam ever been offered?

As good a place as any.

Sunset/3rd rail has done a nice Mikado for the UP. Painted releases in 2R and 3R #2255 ࣔ. It's the only UP prototype I've seen anyone make. Everything else has been the USRA version. Both posted earlier in this thread. 3R versions pop up from time to time in the $500-$800 range. The 2R versions tend to be a little higher for some reason.

The 2-8-0 they released a long time ago seems to have an interesting oddly small proportioned boiler. Having seen so many consolidations offered I settled on the KTM, but that was only 2R.

I'd have to research which series of each prototype actually ran on the specific division you're describing.

Attachments

Nice Lee! I've had stuff in boxes so long I need to get them in a layout!!

Attachments

Well, I'm finally getting back around to my 3rd Rail E7 project. Feels like it's been a year. I managed to clean off the nose herald decal I screwed up the last time I tried to put the repositioned hand grabs on the nose. I learned my lesson and put them on first. I can't believe how shaky my hands have gotten. Meh, life I guess.

Tomorrow I'll get the era correct nose herald decal on and finish with a few dustings of Testors Dull Coat to seal it. Then it's on to the B unit to paint the trucks era correct gray and the tanks to match.

After that I'll post some glamour shots.

Attachments

WITZ Nice !!!

Just for some extra fun.....

A couple of 3rd Rail Diesels.

3rd Rail Union Pacific PA-1 (3R)

3rd Rail Union Pacific E7 A (2R)

The PA-1 stuns me every time I take it out. Awesome details.

I model 1946-1954 so the E7 has been modified to "1948" appearance. I added roof grabs, correct era nose herald, slotted pilot, and painted trucks the appropriate gray.

The PA-1 as 3rd Rail made it has a 1940's through 50's nose herald, late 50's aluminum silver trucks, and late 50's to early 60's dual bulb lamps. So eventually I will modify to late 40's early 50's appearance. I'll replace lamps with single bulbs and paint the trucks gray. I'll also fabricate an Alco closed pilot piece to put in the included fixed pilot. That's why I haven't added the scale coupler up front.

The fixed pilot as I described earlier in this thread is a brilliant and simple switch out on the 3R version even with the powered 3R coupler.

Enjoy!

Attachments

Nice Bud! Thanks for posting.

I like the merger car.

Here’s a video of my Weaver RS-3 with a couple of Custom/ Painted cars I did

Attachments

Love it Lee. I like the early RS units. I wish there'd be enough interest in an RSC-2. I'd love to have a UP one with D.S. numbering, long hood forward with added number boards and marker lights.....

Hello, I have not posted to this thread before, but the UP travels right through our area. In fact the tracks parallel my former route to work (I retired) and when I was lucky I got to see 100+ car freight trains (which also sometimes made me late - LOL)

Here is my Kline Alco S-2 switcher. It earned a prize place on my layout because it can negotiate the 0-27 curves and switches on the inner loop. My only other UP trains are the E-7 AB sitting on the bookshelf beyond the layout in this picture and a lithographed F-3 AA both by Marx and a long way from the scale locos pictured here.

Best Wishes

Don

Attachments

@Don McErlean posted:Here is my Kline Alco S-2 switcher. It earned a prize place on my layout because it can negotiate the 0-27 curves and switches on the inner loop.

Best Wishes

Don

Hi Don. Thanks for posting. This thread is all about the photos and all about the UP!

Love the switcher!

As discussed earlier in the thread I keep it here on the photo album because it's not so much about O/27 vs 3R vs 2R. It's for the photos and videos about O gauge Union Pacific.

I've always been a Union Pacific fan. When I came back to the hobby about a decade ago I found myself frustrated, constantly searching online for actual photos of the UP models available in O before I purchased or considered them. That's kind of why I started this thread. I hope it's fun AND a resource. The cool part is the friends online I've made along the way. Not to mention the huge amount of information I've learned!

Attachments

Well fellows, I can't come close to the beautiful scale locomotives that you have posted. I am afraid that for the most part, they would not operate on my little RR empire with its maximum 31" diameter curves. So I do operate some UP trains, love the colorful livery, and in fact live in a small part of UP territory in Texas. So (just for fun) here is the Marx interpretation of the Alco S-2 which I found that the UP purchased IRL in the mid to late 1940's although their preference was for EMD but their desire for those was blocked by the War Production Board and later by EMD working at full capacity (this IAW what I found on the net).

Here is the Marx Alco S-2 , In UP livery, offered between 1955-1962. It is shorter than scale for sure with only 2 powered sets of wheels and the other two, outboard, sets just going along for the ride.

Here she is pulling a short consist around my "Leonardtown and Savannah" mythical RR. I picked these names because we lived in those towns plus L&S can be nicknamed "long and skinny"...due to space considerations my empire is but 40 inches wide by 17 feet long.

Here is close up of what is likely even less scale, my Marx 3900 UP caboose made 1974-1975

Thanks for all your great posts and marvelous scale engines.

Don

Attachments

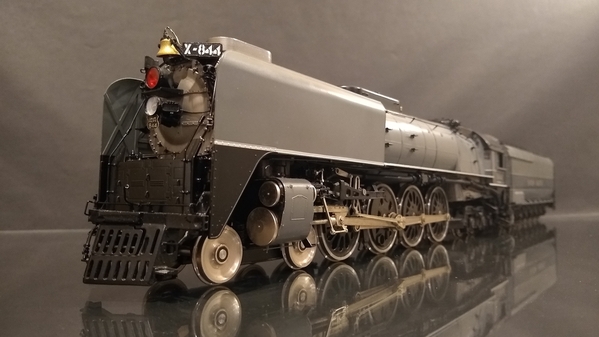

A couple of years ago, I acquired a Lionel Legacy UP 4-8-4 that was unpainted. Over time, I decided that it needed to be painted. So I disassembled the entire engine and tender and took it to my paint shop. I spent several weeks working on cleaning and detailing the engine prior to painting.

After I gave it a coat of primer, I then tackled the paint. The UP grey (Scalecoat) went on first. The black trim; pipes, handrails, and other appliances, were then painted. The cab interior was painted green.

After everything was done, a gloss coat in applied for the decals. Once the decals were set, I then sprayed the finished model with a semi gloss finish.

Although this was very time consuming, I'm very happy with the final results.

RAY

Attachments

Vash, those are friggin awesome.

You just have to fix the pilots on the lead units....😉

@WITZ 41 posted:Vash, those are friggin awesome.

You just have to fix the pilots on the lead units....😉

Thank you! Both Lionel and the Mr. Muffins team did an incredible job putting these models together!

You're also right on the pilots. I need to change them out soon!

Hopefully I'm not reposting here.

UP Heritage "Fallen Flag" units (was a struggle getting them with scale wheels):

UP4014 Big Boy:

UP4141

UP1943

UP1111

UP9096 (I have the Lionel full length excursion cars and the Flag baggage car so I can loosely replicate the President Bush Funeral Train)

Attachments

Beautiful Sarah !

Matt, those diesels are great! Nice pics.

Sarah, Awesome UP type and weathering job. It's fun to watch your works in progress.

Welcome to thread. I look forward to more photos!

@WITZ 41 posted:Matt, those diesels are great! Nice pics.

Sarah, Awesome UP type and weathering job. It's fun to watch your works in progress.

Welcome to thread. I look forward to more photos!

Thank you! Your collection is amazing, I spent maybe an hour scrolling just through this thread.

Here's a little gem that I was lucky enough to buy recently. Very clean for a steam locomotive, I have to change that some day. This is a late Overland model.

Attachments

Glad you enjoyed the thread Sarah. It's been a great time for a lot of UP fans. We keep it here on the photo album because it's about the "seeing" and not just high rail/2R/3RS etc. Looking forward to more contributions from you.

Fantastic switcher. I'm jealous!!

I've been keeping an eye out for one, but the prices always get jacked above what I'm willing to prioritize for it.

Will

Well, given how this year has been going and considering I've been saving and planning for the sizable expense of my C&NW 400 passenger train project. I decided to curtail any other expenditures.

So I resolved to keep my Union Pacific budget locked...

....That is, until someone came along with a Key......

I've been fortunate to have my patience pay off with many fine models acquired at well below value price and try my best to avoid paying top dollar. Sometimes, however, one must pull the trigger when the opportunity is there.

We'll see how she looks when I get my hands on it.

Attachments

Attachments

@Engineer-Joe posted:...

There's just too many roads I like to collect everything.....

Well, Joe. At least we made a valiant effort to pull it off. ![]()

Nice group shot Joe. As Matt has stated before, I keep it to UP (primary) and CNW (secondary). Otherwise I would go broke, or mad, or both.

I also, but not always, aim for 1946-1954.

Helps keep a lid on it. Sort of....

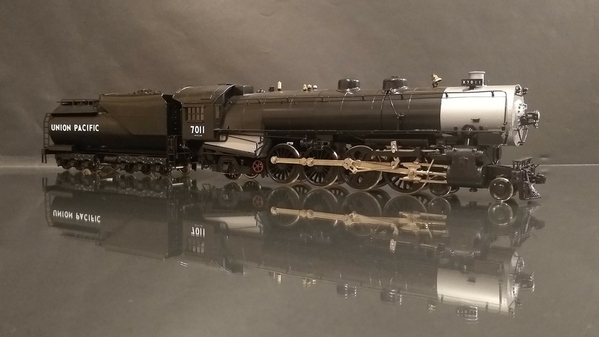

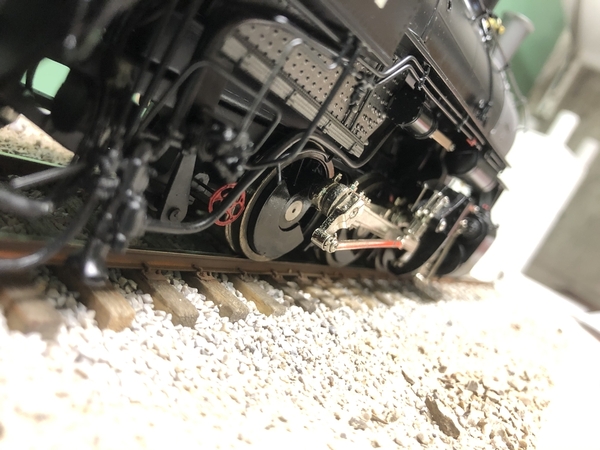

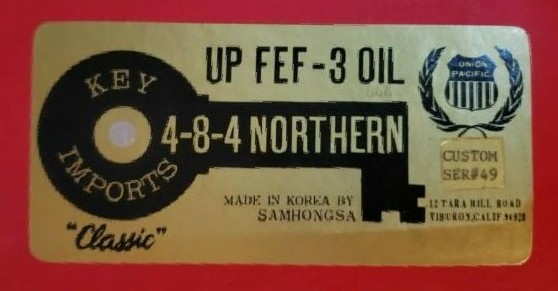

Key Imports FEF-3

Custom Series #49. (In service)

Beautiful model. Appearance falls nicely into my era window. A few things need fixing, and while it runs well, it's a jumper. Could use some better slow speed action. A good candidate for drivetrain work, upgrade, and wheel paint.