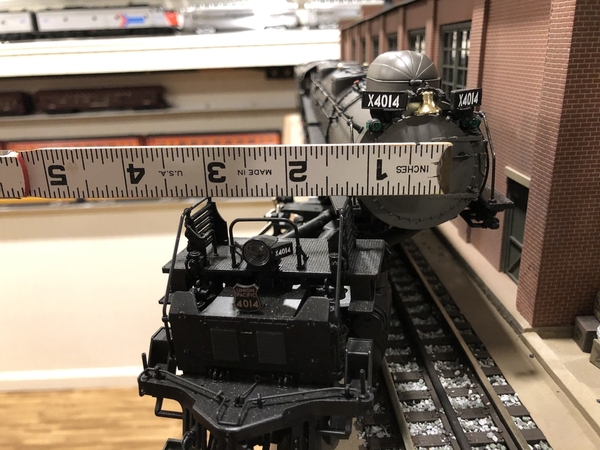

Thanks guys, I'm hoping that soon I'll have lots more videos of more of the dusty stuff on all the shelves and in all the boxes! ![]()

@Dave Funk posted:Congats on your first run!!

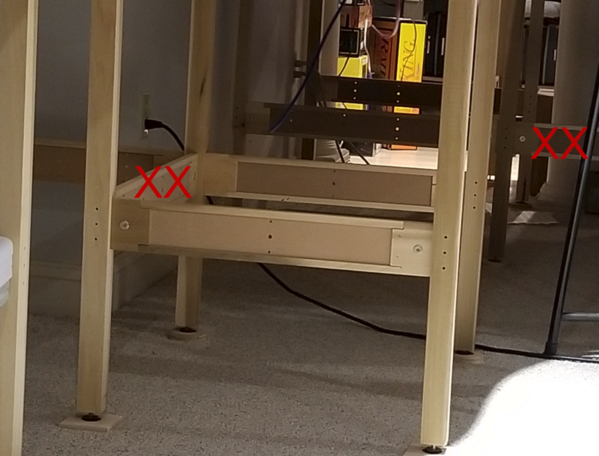

Another 2 weeks and the whole layout will be completed!

Thanks, but the only way this gets done in two weeks is if 20 people show up and all work together! ![]()

![]()

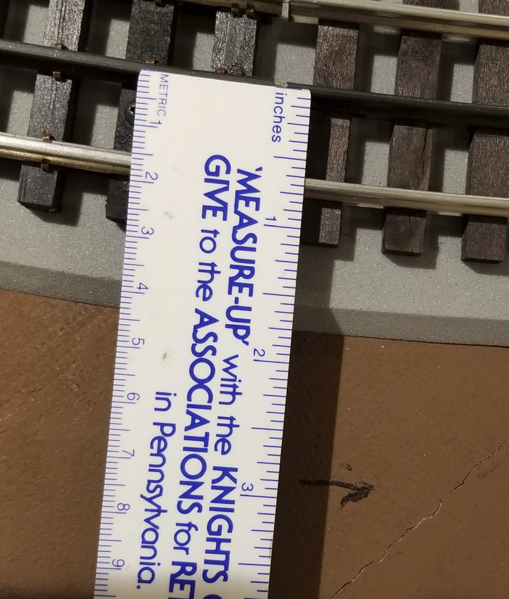

@Dennis-LaRock posted:John, I know you going to be running 'modern' controllers (radio/computer etc.) switch/block system... but, are you going to build an old school control panel as well?

I will have a control panel with the switches and turntable controls. However, all the power districts, sidings, switches, and the turntable will be TMCC controlled. I should be able to run pretty much everything from the TMCC/Legacy remote. I have a box of Lionel SC2 controllers that have been waiting for something to do, they're getting their chance now! ![]()