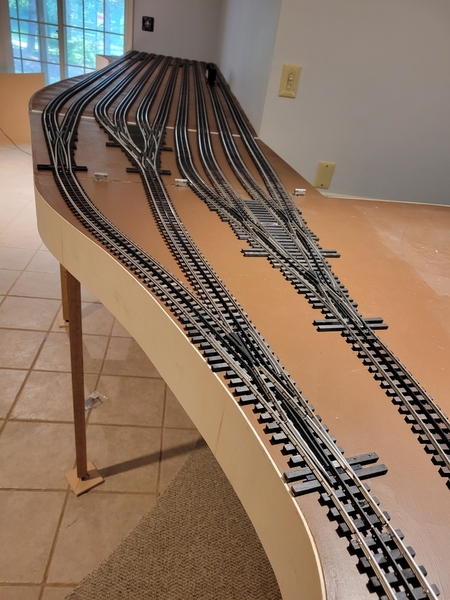

@gunrunnerjohn posted:Yep, since it's a yard track and it'll be slow speed operation with anything going down that line, I figured I'd shoot the dice. In order to keep the curves at O72 or larger on all the tracks, that's where the track ended up. I could have done even more ripping up to move it a little, but I decided it wasn't worth the trouble.

I like your way of thinking John, once its down, move it as little as possible!

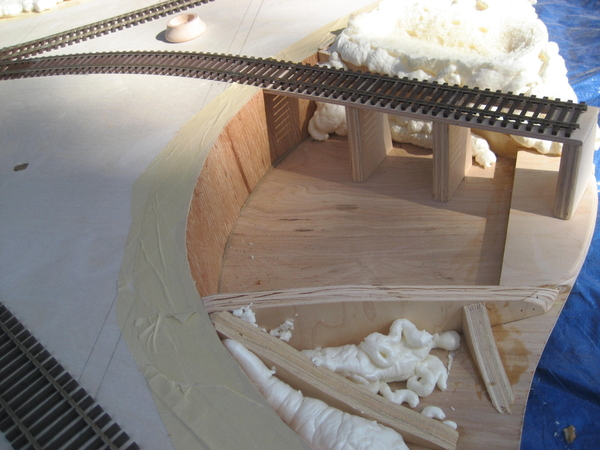

Upper level proped up

Upper level proped up