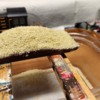

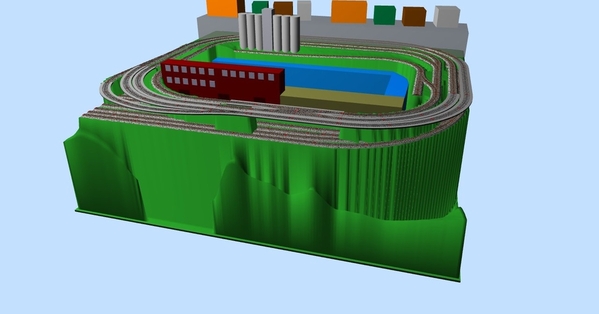

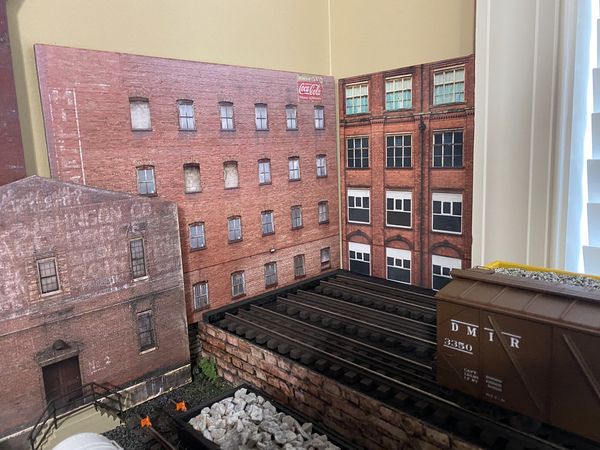

Sometimes I just wonder where these posts should go - since this is currently on my layout and will be on the workbench later, "now" trumps. These silos started life as carpet and flooring tubes - 4 inch OD and 12 feet long. Amazing how such a long tube turns into nothing after a few quick cuts.

I think the dimensions/proportions look about right - these are 22" tall, (the 24" tall version looked too tall). The elevator building and top side conveyor building will be added later. While I would prefer these to be on a back wall somewhere, this is the only suitable spot I have without compromising other wants. The idea here is to have the unloading cars on the high rail behind the silos, loading cars in front (as seen) and barge loading in the wharf area.

Most O scale kits have the silos around 14 inches tall - so do I cut these down or leave them tall? While I would like not to obscure the town view, these are massive structures - they are all over the place in Central Illinois. On the other hand cutting these down to 14 inches would leave them 1 inch above the retaining wall of the town leaving a clear view of the town. What do you all think? Here is that "compromise" word again. Thanks for looking/commenting ... Jeff

@Alan Graziano Alan if you see this post, wondering how you would approach this given your expertise in building everything in O scale industries.