My eight year old granddaughter qualifying on the main line.

@Jstewart204 Looks like the really fun part of layout building! LOL I guess some folks enjoy it, as for me it hurts my brain!

@Odenville Bill Bill I sure hope you find the short! and it turns out to be an easy fix!

@Tranquil Hollow RR Nice to see she is starting early in life! What a good grandad to keep her intrested!

I know its not quite what I did on the layout today but its a start! We got our new train room with attached house! I am just not sure what room the CEO is going to let me have! LOL

I hope you all have a great weekend and find time to have fun with your trains and layouts!![]()

Attachments

Congratulations Mike! Let the fun begin.

@mike g. posted:I know its not quite what I did on the layout today but its a start! We got our new train room with attached house! I am just not sure what room the CEO is going to let me have! LOL

I hope you all have a great weekend and find time to have fun with your trains and layouts!

Congratulations Mike, I’ll be looking forward to following your journey into the new train room.

Gene

looks like a good start mike

That’s great Mike, congratulations. Home buying has to be one of the most frustrating experiences. Let the planning begin.

Jay

Yay Mike! Congratulations. This, again, is going to be fun to watch. Before you begin, remember it's the journey...

Dave

Hey Mike, You have a great looking place there. Especially a room for your layout. "Good Luck" on your negotiations with the CEO. I got lucky with mine many years ago. She now tells visitors I left her enough room in the basement for a washer and dryer! Bill

Hey Mike. didn't you guys move done there to be closer to grandkids. You have to get one of grandkids on your side. They can get just about anything from the CEO. lol

Hey Mike, You need to listen to us. That was more good advice from Ohio Jeff. I bet there are many good suggestions that will come if you need our help.

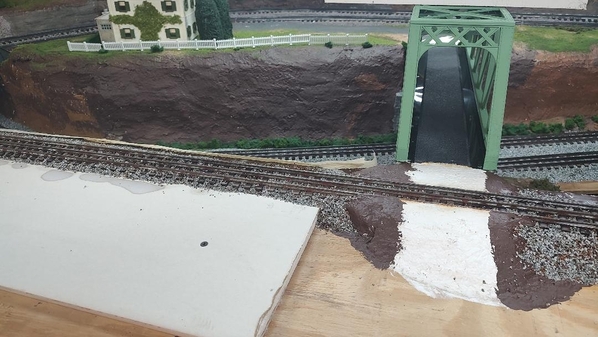

Here are some pictures of present work done the last several days on the Maybrook area of my layout. The gates go up and down perfectly, but not in conjunction with the sensors. Still need work but they do look awfully good. In placing buildings around the area, I settled on using !/2" sheet rock cut to look like concrete pourings for bases. Then I took a page out of Pete Condro's book using foam core for the roadways. Those sections were cut and painted and will be installed tomorrow. The curbs will be a little high, about a 1/16th" but by the time I glue down the foamcore, it might be much closer to the desired height. I also ballasted the spur track coming into the freight house. Again I used the 1/2" sheet rock for the freight house base. Before I am finished with the bases , I will scribe section marks on the them and wash them with a light solution of india ink and alcohol. In several cases I will scour them a bit and add some green turf to look like broken concrete. As for the ballast, my own rule of using plenty of wet water and glue shows with the puddles of white glue coming out of the ballast.

Attachments

The crossing gates do look good, Bill. The description of the building base and road sound like a good plan.

Morning guys thanks for all the kind words!

@Ohio Jeff we moved down here from Washington to be closer to my wife's family, left the grandkids behind. As the grew they had no interest in Model trains. The good news is my nephews are totally excited to help rebuild and they are both in there 20's.

@Bill Park Your layout is looking great and I like how you explain your process for building the base and roads! You are correct about suggestions here! I have been taking advice from the first day I joined this forum!

Well i tried to help you, Mike. The 20 yr olds will be good for helping on the layout. Strong backs and young knees are very heplful.

Hey Mike, Most of us on here have a CEO above us. Hopefully we collectively know all the tricks.

@mike g. posted:

Looks great Mike!

@Bill Park posted:Here are some pictures of present work done the last several days on the Maybrook area of my layout. The gates go up and down perfectly, but not in conjunction with the sensors. Still need work but they do look awfully good. In placing buildings around the area, I settled on using !/2" sheet rock cut to look like concrete pourings for bases. Then I took a page out of Pete Condro's book using foam core for the roadways. Those sections were cut and painted and will be installed tomorrow. The curbs will be a little high, about a 1/16th" but by the time I glue down the foamcore, it might be much closer to the desired height. I also ballasted the spur track coming into the freight house. Again I used the 1/2" sheet rock for the freight house base. Before I am finished with the bases , I will scribe section marks on the them and wash them with a light solution of india ink and alcohol. In several cases I will scour them a bit and add some green turf to look like broken concrete. As for the ballast, my own rule of using plenty of wet water and glue shows with the puddles of white glue coming out of the ballast.

Looks good Bill. Can never use too much glue.......![]()

Bob

@Mike g.

Yes Mike definitely a right move to a new train room. So glad to learn the nephews might have talent and plan to assist

keep us posted on the room you have negotiated with management…

a good day to you both

I enjoyed running the train’s yesterday evening after covering the blooming bushes with old sheets. I’m getting in lots of practice with the sheets this spring.

I opened the windows and blew the engine horns. Lots of fun…

Carefully disconnected the wires and took the steel mill off of the layout to do some additional painting and then weather. Here you see where I have started masking off certain areas of the structure, including the track inside of it.

Dave

Attachments

Given the quality of your work, this will be a show piece. Looking forward to seeing the results.

Jay

@luvindemtrains posted:Carefully disconnected the wires and took the steel mill off of the layout to do some additional painting and then weather. Here you see where I have started masking off certain areas of the structure, including the track inside of it.

Dave

Dave, with your talent, piece of cake. Looking forward to seeing the results.

Gene

Thank you both gentlemen. This will be a first but I'm going in...

Dave

Dive! Dive! I’m sure it will look great, Dave!! 👍🏻😃

Mark,

Thanks for your vote of confidence. I'm imagining you and others standing around me with my mask on and paint in hand trying to make it happen, lol.

Dave

We will watch and learn Dave.

@luvindemtrains posted:Mark,

Thanks for your vote of confidence. I'm imagining you and others standing around me with my mask on and paint in hand trying to make it happen, lol.

Dave

That’s right Dave!! 😃 I think where I mess up is not getting a good seal when masking and a little bit of paint seeps under. 🙁

Hi guys thanks for the kind words and I will keep you posted on how things go for a the new train room location! LOL

Till then you all keep up the wonderful work!

@luvindemtrains Dave I cant top alot of what has already been said about your work! But I still want to put my 2 cents in and say I think it is just AMAZIUNG!![]()

Thank you Mike. I appreciate that.

Dave

Hey y'all,

I've been working on the railroad. In my last post I was chasing a short on the main line. The offending part was switch #4. The MOW crew replaced it with a 10" piece of track. The main line is open. I'll check out the switch this evening. I wanted to run a train. My Lionel 681 steam engine pulled my new-to-me Prince Albert reefer and my favorite caboose.

Thanks for looking.

Attachments

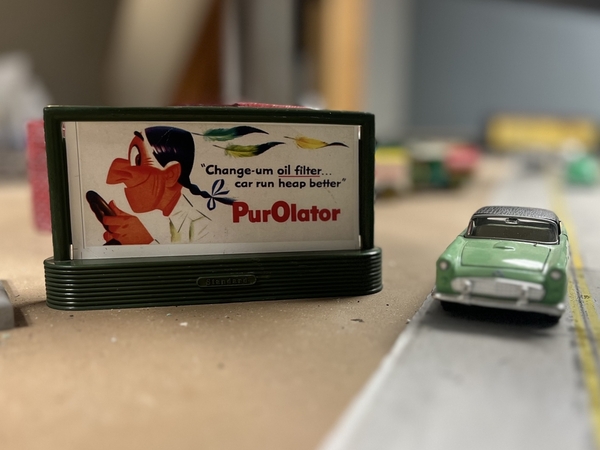

A new addition to the layout, the Menards Cavana Tower. This was the perfect venue to finally get more of my die-cast cars out of boxes and on display. I had to place it next to the existing exotic car store. BTW, that store got a new set of showroom lights using the plug n play lights from Menards.

Attachments

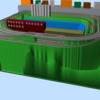

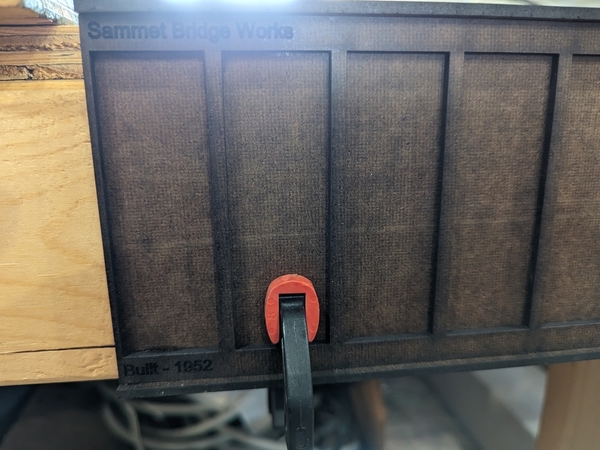

I have 2x4 table legs for my train table like a lot of people do but I working on dressing the legs up a bit. I have laser cut some face pieces that will wrap around the 2x4's to make them look like bridge piers. I will be painting the legs brown before applying the face pieces. Comments are welcomed on my project to see if it is worth doing for all of the legs.

I also plan to cut a girder side to attach to the exposed 2x4 face all the way around the table to make the layout appear that it is setting on girders with piers under the girders.

idea-thinker

Attachments

@idea-thinker posted:I have 2x4 table legs for my train table like a lot of people do but I working on dressing the legs up a bit. I have laser cut some face pieces that will wrap around the 2x4's to make them look like bridge piers. I will be painting the legs brown before applying the face pieces. Comments are welcomed on my project to see if it is worth doing for all of the legs.

I also plan to cut a girder side to attach to the exposed 2x4 face all the way around the table to make the layout appear that it is setting on girders with piers under the girders.

idea-thinker

Great idea. I like it

@Odenville Bill posted:Hey y'all,

I've been working on the railroad. In my last post I was chasing a short on the main line. The offending part was switch #4. The MOW crew replaced it with a 10" piece of track. The main line is open. I'll check out the switch this evening. I wanted to run a train. My Lionel 681 steam engine pulled my new-to-me Prince Albert reefer and my favorite caboose.

Thanks for looking.

Bill, you have done a lot on your layout since I have seen a video! It looks great! I’ve heard of Prince Albert in a can but not Prince Albert in a reefer! It looks great!

They look awesome idea thinker

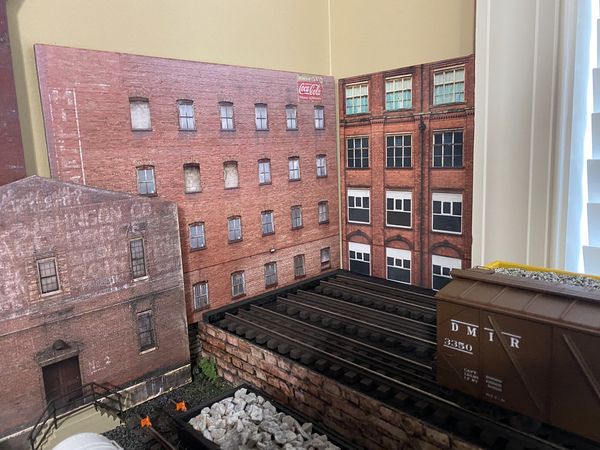

With all the added repaint projects to my freight car roster, I find myself running out of track storage. Add 18.5 feet of yard storage by utilizing the window sill. Yesterday I picked up a 4x4 piece of 1/2” particle board to provide a base for 6 - 37” sections of used GarGrave tin plate track. The track arrived today and it and the base will be painted next week. A new higher brick retaining wall will be added along with some printed building flats to finish the scene. I'm still able to avoid weathering!

Cheers, Dave

Attachments

Dave,

Great idea, and very clever to add scenery.

Dave

@darlander posted:With all the added repaint projects to my freight car roster, I find myself running out of track storage. Add 18.5 feet of yard storage by utilizing the window sill. Yesterday I picked up a 4x4 piece of 1/2” particle board to provide a base for 6 - 37” sections of used GarGrave tin plate track. The track arrived today and it and the base will be painted next week. A new higher brick retaining wall will be added along with some printed building flats to finish the scene. I'm still able to avoid weathering!

Cheers, Dave

Good idea Dave. I've grabbed every available horizontal surface as well.....and created a new one too.....![]()

Bob

Attachments

Nice job Dave and Bob making use of what available space you have! I have a similar problem with very little space and too much to put in it! 😄

Wired up the newer CUlvert Unloader and Oil Drum Loader post York.....

Have a safe and great weeknd, everyone!

Peter

Attachments

Great work everyone!

@Odenville Bill I am glad you found the short! I hope you can get the switch fixed so you can get your layout back to the way you planned on to be!

@idea-thinker Love the laser gut idea! I am now saving up for a 3D printer, maybe a laser cutter will be next! LOL![]()

@darlander Dave, you have to get the space where you can! I know I will be looking for places as the CEO wont be giving up anything in the house! LOL

@Putnam Division Peter nice addition of the Culvert Unloader and Oil Drum Loader, Every time I look you have something new and exciting to share!

As for me nothing new, just working on getting inspections done on a possible future home. I am getting excited to get the boxes of my trains out of storage and in a new home location! I hope you all have a great week and don't work to hard! Oh and for those needing don't forget the nice Malt drink as needed! LOL

I hope you all find time for your layout and have fun with your trains!![]()

I was VERY busy this past weekend, working on completing the fascia for the entire layout. This is 3/16" hardboard cut to 4" tall strips with a few 2" strips over the shelving area.

As I started the fascia, I realized it would be a great time to work on this three track tunnel entrance going under the town.

The girder strip is from East Coast Enterprises and the walls are from Scenic Express.

- Jason

Sometimes I just wonder where these posts should go - since this is currently on my layout and will be on the workbench later, "now" trumps. These silos started life as carpet and flooring tubes - 4 inch OD and 12 feet long. Amazing how such a long tube turns into nothing after a few quick cuts.

I think the dimensions/proportions look about right - these are 22" tall, (the 24" tall version looked too tall). The elevator building and top side conveyor building will be added later. While I would prefer these to be on a back wall somewhere, this is the only suitable spot I have without compromising other wants. The idea here is to have the unloading cars on the high rail behind the silos, loading cars in front (as seen) and barge loading in the wharf area.

Most O scale kits have the silos around 14 inches tall - so do I cut these down or leave them tall? While I would like not to obscure the town view, these are massive structures - they are all over the place in Central Illinois. On the other hand cutting these down to 14 inches would leave them 1 inch above the retaining wall of the town leaving a clear view of the town. What do you all think? Here is that "compromise" word again. Thanks for looking/commenting ... Jeff

@Alan Graziano Alan if you see this post, wondering how you would approach this given your expertise in building everything in O scale industries.

Attachments

Jeff, I agree that sometimes I don’t know if something like this should be on the layout thread or the workbench thread. As far as other people’s posts go, I don’t care which thread they use.

I have only seen grain silos like you are building twice, that was on two trips to Mattoon, Illinois which is the location of the headquarters for the company that bought North Pittsburgh Telephone where I worked. If you didn’t have the town behind, then these are great. However, cutting them down to the height of the retaining wall would not look right in my opinion. Maybe you could split the difference and see how that works out.

@jdstucks great looking g fascia! It really dresses up the layout and love the 3 track entrance.

@ScoutingDad Jeff if it was me I would cut them down. I used Pringle cans for my Menards Morton salt building.

Attachments

@jdstucks fascia looks nice and clean as it really dressed up the layout.

@ScoutingDad posted:Sometimes I just wonder where these posts should go - since this is currently on my layout and will be on the workbench later, "now" trumps. These silos started life as carpet and flooring tubes - 4 inch OD and 12 feet long. Amazing how such a long tube turns into nothing after a few quick cuts.

I think the dimensions/proportions look about right - these are 22" tall, (the 24" tall version looked too tall). The elevator building and top side conveyor building will be added later. While I would prefer these to be on a back wall somewhere, this is the only suitable spot I have without compromising other wants. The idea here is to have the unloading cars on the high rail behind the silos, loading cars in front (as seen) and barge loading in the wharf area.

Most O scale kits have the silos around 14 inches tall - so do I cut these down or leave them tall? While I would like not to obscure the town view, these are massive structures - they are all over the place in Central Illinois. On the other hand cutting these down to 14 inches would leave them 1 inch above the retaining wall of the town leaving a clear view of the town. What do you all think? Here is that "compromise" word again. Thanks for looking/commenting ... Jeff

@Alan Graziano Alan if you see this post, wondering how you would approach this given your expertise in building everything in O scale industries.

@ScoutingDad have you considered moving the silos down and omitting part of the water area. You could always use one of the corrugated style (Sea Walls) after the silos so you could still have a smaller water area. You could even have a barge there getting filled with grain or what ever you are using the silos for. Just a couple ideas for you.

@ScoutingDad, I like the silos tall but don't like the obstruction of your nice town buildings. How about only using 3 silos left tall? Just my 1 1/2 cents....

Mike

Attachments

@ScoutingDad Jeff- I'm in the less is more camp. Fewer silos and shorter.

@Oldegreybeard- You don't see adds like that anymore.

@jdstucks- The fascias look great. Gives a nice finished appearance to the front of the benchwork.

Bob

Jeff

It looks like you will have three silos on each side of the elevator/ machinery building.

The layout seams fine. The material you are using will require using a glue gun to assemble. I would stay with cardstock and mdf material. When I build I use abs or styrene materials so I can use solvent glue for 95 percent of my assembly.

if you want to change the layout, you can put a double row of three silos with the building on one end.

if I did not give you enough of an answer, send me an e mail.

@ScoutingDad posted:Most O scale kits have the silos around 14 inches tall - so do I cut these down or leave them tall?

Per Wikipedia there is no standard sized silo. So make it what height you want.

Hi all, thanks for the helpful replies. The forum really helps bounce ideas around I may have not thought of - that is really valuable to me - thanks.

I am still considering options, but I am leaning toward cutting the silos down a little such that they are no taller than the first floor of the buildings behind. So going from 22 tall to 16 to 18 tall. There is 8 inches of space on the deck = not enough room for a silo double stack and a track. Unless I use tighter track curves I do not have room to add a couple of inches for the 2nd silo row and it would increase the approach grade. Thought about moving or reconfiguring the area - a possibility - a better solution would be a bigger train room which equals a new house.

Various types of silos are all over central Illinois. It is hard to recognize how tall these things are given they are the only tall structures in an essentially flat landscape. Even the towns built around them are dwarfed by their size. Many newer ones are huge corrugated steel structures or large area concrete low-wall covered "bins". Just trying to model what I have gotten used to seeing over the years.

Jeff, that sounds like a good height. You will still be able to see the buildings in the town.

@scoutingdad... My cement silos model from L&NE Martin's Creek, PA are based upon prototype style and height.

Walter

Chris Hughes photo...NOTE: photo removed due to copyright per OGR TOS

Attachments

@jdstucks Nice job! The fascia gives the whole layout a professionally built appearance.

I've used both of the products that you used at the portal. The walls as seawalls and the girder strips provided a fascia for my upper level of the layout which is a different scene.The strips are painted black. They are below the concrete fence.

You present a conundrum. The few industrial silos that I have seen in my travels around the country were massive and controlled the whole scene. I think that will be true on your layout; viewers eyes will be drawn to the silos and possibly miss other creations that you have made. Although already in place, my thoughts are to raise the town scene behind the silos; or lower the area of the silos. Definitely not an easy task.

Attachments

@pennsyfan Bob, Had not thought about raising the town. All the back sections are on 1 1/2 foam board, with no wiring as yet. Other than making additional retaining walls its relatively easy. Of course then I would need a ladder to work on the town. Food for thought. I am planning a trolley line back there, so access is needed.

Your comment on dominating the scene (although prototypes really do) is spot on. I am not looking for these to be statement pieces - so reducing the height may be the compromise. THX

Quick question... other than preference is there a reason why to build Ore Load with a false bottom? Is it to just save on the ore? And why glue it down? Seems like it would be ok just to fill them up with your ore of choice and be done. Is there a weight concern, or concern if it derails it will make a mess (like in real life).? Just curious. Working on a couple.

@CR Cole posted:Quick question... other than preference is there a reason why to build Ore Load with a false bottom? Is it to just save on the ore? And why glue it down? Seems like it would be ok just to fill them up with your ore of choice and be done. Is there a weight concern, or concern if it derails it will make a mess (like in real life).? Just curious. Working on a couple.

Huge waste of material. I've built mine on the plastic loads supplied with the car, and just sit them in the car. Allows for removal so that you can run empties or loads as you like.

Foam core or core board can be used as a base to build a load on for cars that don't have fake loads. And yes, a derailment could lead to a big clean up in aisle 12.

Attachments

It’s not what I did but what my buddy Keith delivered today. It’s the pedestal for the transformers and it has wheels that lock. There will be an angle board to mount the switch controllers and related items. If I could get my car on top of it, the weight would be supported.

Jay

Attachments

@Tranquil Hollow RR posted:It’s not what I did but what my buddy Keith delivered today. It’s the pedestal for the transformers and it has wheels that lock. There will be an angle board to mount the switch controllers and related items. If I could get my car on top of it, the weight would be supported.

Jay

Looks like it would hold a 500KVA transformer. Should be fine for a toy train transformer.

Your friend does nice work.

Bob

I’m very fortunate and he also built my bench work. If there is an hurricane or tornado, we’re going under the layout.

And, we both enjoy triple distilled spirits.

@RSJB18 posted:Looks like it would hold a 500KVA transformer. Should be fine for a toy train transformer.

Your friend does nice work.

Bob

You beat me to it, Bob!! Jay, your friend did a great job!!

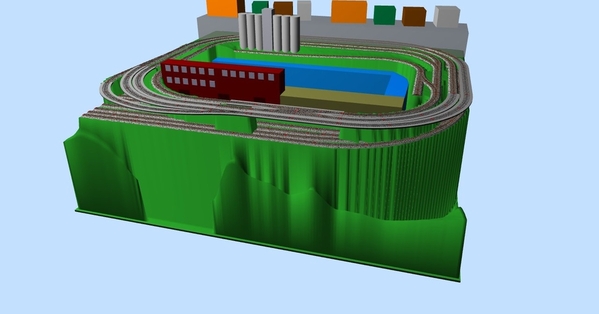

I am not very good at SCARM but here goes - This is a view of what I would see if standing where I usually run trains. The silos were cut down to 18 inches from 22 - that seems to make a difference. The red-brown building is a freight (future) warehouse to service the yard and mate up with the water on the other side. Three stories tall on the track side, two stories on the water side with room on the water side for semi-trailers.

Attachments

That looks like a good rendition of your main structures and elevations, Jeff. I think 18” is a good compromise. That is quite the freight house you plan; a testimony to a very busy railroad!

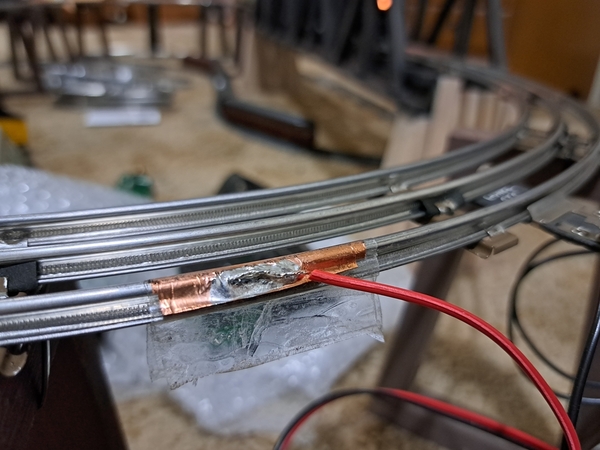

I recently got my first Marx accessories including a #418 Bell Ringing Crossing Signal. The instructions mentioned a track clip that, it seems, would allow the bell to ring intermittently as wheels roll over, as opposed to one long ring that you'd get with a full-length section of insulated outer rail. Robert Grossman Marx parts showed one clip that it says is a little big for 027, which I'm using, so I decided not to order. I found descriptions of the clip online where posters described various methods of making your own. Tonight I tested my own method. I taped a 2" piece of clear packaging tape over the outside rail. Then I applied inside of that a 1.5" piece of copper foil tape I got from Hobby Lobby. (Diamond Tech "Studio Pro" Stained Glass Foiling tape 1/4" x 36 yds copper. I initially made a mistake and found that this copper tape has the best adhesive in the world. It just sticks.) It doesn't sound great I think because I've got my finger on the bell, but it does sound the bell intermittently as the individual wheels roll over so I'm happy.

Attachments

@John's Trains posted:I recently got my first Marx accessories including a #418 Bell Ringing Crossing Signal. The instructions mentioned a track clip that, it seems, would allow the bell to ring intermittently as wheels roll over, as opposed to one long ring that you'd get with a full-length section of insulated outer rail. Robert Grossman Marx parts showed one clip that it says is a little big for 027, which I'm using, so I decided not to order. I found descriptions of the clip online where posters described various methods of making your own. Tonight I tested my own method. I taped a 2" piece of clear packaging tape over the outside rail. Then I applied inside of that a 1.5" piece of copper foil tape I got from Hobby Lobby. (Diamond Tech "Studio Pro" Stained Glass Foiling tape 1/4" x 36 yds copper. I initially made a mistake and found that this copper tape has the best adhesive in the world. It just sticks.) It doesn't sound great I think because I've got my finger on the bell, but it does sound the bell intermittently as the individual wheels roll over so I'm happy.

Creative thinking John. Nice work.

Bob

@RSJB18 posted:Creative thinking John. Nice work.

Bob

Thank you, Bob. I haven't tried soldering it yet. The copper tape is designed for soldering stained glass, but I don't know if the heat will destroy the packaging tape's electrical insulation.

John

Continued painting the steel mill (cast house). Broke a few pieces off in the process but they were pretty simple to reattach. I may be able to start weathering before the week is out. Here's a peak..

Dave

Attachments

That’s going to be sooo impressive Dave.

Today, May 1, 2024, was wash day for the caboose...no not O or G or even HO gauge but a true scale 1:1 caboose. CNJ #91545. It sits on about 85ft of prototype CRR-NJ rail rolled in the early 1900's with actual full size railroad ties and proper stone ballast. So I guess this can be considered a layout, albeit a little larger size.

Every year in the spring the caboose is washed and every 5 years or so completely repainted. This year CNJ #91545 , which was built in May of 1942, turned 82 years old. Happy Birthday!

Attachments

@Walter Matuch . So I guess this can be considered a layout, albeit a little larger size.

Yes sir Walt , if this is in your back yard it would definitely be considered to be your layout getting taken care of. ![]() I'm guessing that might be you on that ladder.......if so , you're looking in good health sir.

I'm guessing that might be you on that ladder.......if so , you're looking in good health sir.

HAPPY 82nd 91545.

Beautiful caboose. Thanjs for posting. Is this part of some historical society?

Tom

Dallas Joseph...Not me on ladder. I am spraying water with hose to wash off the soap. Feeling good and am about 7 years younger than the caboose.

PRR8976...Privately owned by my wife and me. Not associated with any society or group.

Walter

I have finished the other part of my Pier, and Girder facing for the edge of my layout and the legs. The Girder part is intended to coverup the 2x4 edge of the layout itself and face parts of the leg will cover the 2x4 legs. I will be painting the 2x4 legs a darker color to match the color of the Laser Cut pieces I am cutting.

idea-thinker

Attachments

@idea-thinker Very unique! ![]()

Tom

Idea thinker, your piers will look great! You certainly have a knack for thinking outside the box, with amazing results.

Rich, Your progress looks great! I've been saying "pardon the mess" for over 5 years. 'Eventually' is the word of the day!!

Today I completed, at least for now, the window sill storage/display yard. Added some printed flats on each side of the window and a new stone retaining wall. Track is painted but I do not think I will be adding ballast. The buildings and stone wall are pinned in place but everything else is resting in place. Easy to modify or remove as the spirit moves me. Now I have room to add more repaints as they become available. This coming Saturday is the biannual Twin Cities Model RR Club train show so I will attend with an eagle eye for new projects.

Cheers to all, Dave

Attachments

Very nice job, Dave!

@darlander posted:

Those printed flats and stone wall look really good. I especially like how you combined the 3-dimensional stairs with the flat building. It kind of tricks the eye.

That is an excellent use of the flats on the corners.

Jay

Last week I experimented with using copper stained glass tape and clear packaging tape to make an insulated power contact for a new-to-me Marx #418 Bell Ringing Crossing Signal. the contact is less than 2" long so it makes the bell intermittently ring as each wheel crosses. I wasn't sure if I'd be able to solder it without melting the tape. I found it worked better first soldering the wire to the copper tape on the workbench and then sticking it over the clear plastic tape that's already on the rail. Not pretty but the bell ding-dings as the wheels pass.

Attachments

@Tranquil Hollow RR posted:I’m very fortunate and he also built my bench work. If there is an hurricane or tornado, we’re going under the layout.

And, we both enjoy triple distilled spirits.

The table looks great and with the rest of your layout built buy the same friend I can understand why you would be under it during a tornado! The good thing is now that I live in Tornado ally I know how strong I need to build my layout! LOL![]()

Hi guys and gals, I have to say your all doing amazing stuff, but then again, I wouldn't except anything less from all your hard work!

I had to go back a page to see what you all were up to, I hate to say that with all the great work there is to much for me to comment on everyone's work! All I can say is I wish I had something to add to the forum page here!

I hope to be back to building soon as we will be closing this month and after getting everything settled I will have to start thinking about train room size. It all depends on how much room I want to leave for a work shop and how much I want for a train room. I have a 20' X 30' shop to work with! I am open to ideas, I have been thinking 20' X 20 but no bigger! Please give me your thoughts!

I hope you all have a great week and find time to have fun with your layouts and trains!![]()

@mike g. posted:....I have a 20' X 30' shop to work with! I am open to ideas, I have been thinking 20' X 20 but no bigger! Please give me your thoughts!...

Mike, you are blessed that you have that size to work with! Your idea sounds good.

John

Mike, thinking long and narrower would be more useful than square. Tough to get in folded dogbones at 20 feet assuming 072 minimum. I would love to have the space for a walk in layout. How long was the room for your previous layout?

@mike g. posted:Hi guys and gals, I have to say your all doing amazing stuff, but then again, I wouldn't except anything less from all your hard work!

I had to go back a page to see what you all were up to, I hate to say that with all the great work there is to much for me to comment on everyone's work! All I can say is I wish I had something to add to the forum page here!

I hope to be back to building soon as we will be closing this month and after getting everything settled I will have to start thinking about train room size. It all depends on how much room I want to leave for a work shop and how much I want for a train room. I have a 20' X 30' shop to work with! I am open to ideas, I have been thinking 20' X 20 but no bigger! Please give me your thoughts!

I hope you all have a great week and find time to have fun with your layouts and trains!

Congratulations Mike that’s a good size canvas you have to work with. You might consider what prep work you want to consider; lighting, additional outlets, ventilation, and what you might want as a backdrop. My vote is always bigger is better but consider access around the perimeter and in the middle. Just for fun use painters tape on the floor to give you a perspective. It’s going to be exciting to see how your project develops.

Jay

Hi guys thanksnfor the input so far.

@ScoutingDad Jeff my old layout room was 12'w X 24' L.

I could possibly do a 10' X 30' but that wouldn't really leave me room to big reverse loops.

But I am open to ideas!

Yep but you could do an 'L' shaped room to gain the room for reversing loops. A 10x20 workshop is still good sized. I would consider a helix in a space like that (10x10) to gain vertical for upper level track.

@ScoutingDad posted:Yep but you could do an 'L' shaped room to gain the room for reversing loops. A 10x20 workshop is still good sized. I would consider a helix in a space like that (10x10) to gain vertical for upper level track.

Hi Jeff, I would think about a helix, but I do t have enough MTH scale trak and don't know if any other manufacturers mate up with it without a lot of work.

@mike g. posted:Hi guys and gals, I have to say your all doing amazing stuff, but then again, I wouldn't except anything less from all your hard work!

I had to go back a page to see what you all were up to, I hate to say that with all the great work there is to much for me to comment on everyone's work! All I can say is I wish I had something to add to the forum page here!

I hope to be back to building soon as we will be closing this month and after getting everything settled I will have to start thinking about train room size. It all depends on how much room I want to leave for a work shop and how much I want for a train room. I have a 20' X 30' shop to work with! I am open to ideas, I have been thinking 20' X 20 but no bigger! Please give me your thoughts!

I hope you all have a great week and find time to have fun with your layouts and trains!

Mike- think about swinging a 4x8 sheet of plywood around......I'd lean toward more of a 50/50 split for shop/ trains. You can always plan on opening a garage door as overflow space too. I do my bigger woodworking projects in my 2 car garage and find it a bit confining at times.

Bob

@mike g. posted:I hope to be back to building soon as we will be closing this month and after getting everything settled I will have to start thinking about train room size. It all depends on how much room I want to leave for a work shop and how much I want for a train room. I have a 20' X 30' shop to work with! I am open to ideas, I have been thinking 20' X 20 but no bigger!

Mike, great news! I certainly don’t have enough experience on a layout design, but I’m sure you’ll plan what’s best for you.

Gene

Mike:

Start by deciding how much space you need for a workshop and then figure how to partition off part of your 20' x 30' space to accommodate your layout plan.

For backdrops, I like mirrors. They "double" the size of your layout.

Our zoo scene butts up against a mirror. The giraffe pen is the last pen before the mirror. The road next to the zoo seems to continue for quite a long way. But close observation of the photo shows duplicate buildings beginning with the 4th visible building on the left. Also, there seem to be 2 Coca Cola delivery trucks facing each other on the road next to the zoo wall. The on farthest away is a mirror image.

The photo below is at the corner of the room. The duplicate blue walled skyscraper toward the top right of the photo is where the mirror, perpendicular to the mirrors across the back of the layout, is placed. The perpendicular alignment of a mirror against another mirror effectively quadruples the view of the scene. Our layout viewers find the mirrors very effective.

The scrap yard is up against the front wall of the house. The passing train and all of the visible buildings in the scene are mirror images.

I find the use of mirror backdrops to be a great way to make a smaller layout larger.

Attachments

I found a store front I liked for my parking garage tunnel. Store front started as a high quality N scale model. Scaling to over 250% brick details are still good. Then made some windows for it. Tried my 3D pen for the first time using it to weld the printed parts together. Worked great. Then I updated the layout of the city area of my elevated rail. Lights are mellower than the picture shows. May add some weathering to bring out to the storefront detail later.

Attachments

Morning guys first off I want to say I hope everyone is safe where the Tornados touched down in Texas, Oklahoma, Kansas and Missouri. I know they say 2 touched down near Joplin Mo. where we bought our new home!

@VHubbard Great looking setup for your garage tunnel! That is what I call thinking out of the box!

@RSJB18 Bob, I know what you are saying, even thought our new house has a 2 car attached garage it will only be used for cars. The shop will be for wood working and layout building!

@Genemed Neither do I but I know there are a lot of folks here on the forum, This place has an answer for almost any question that comes up. I am really leaning towards the 20' X 20' room for a layout. The only thing that could change this is if my truck wont fit in the attached garage! LOL![]()

@Randy Harrison I love the idea of mirrors and have tried a couple on auto tunnels on my old layout to make it look like it really went somewhere!

I hope you all have a great day and find time to have fun with your layout and trains!![]()

@mike g. posted:@mike g. posted:I hope to be back to building soon as we will be closing this month and after getting everything settled I will have to start thinking about train room size. It all depends on how much room I want to leave for a work shop and how much I want for a train room. I have a 20' X 30' shop to work with! I am open to ideas, I have been thinking 20' X 20 but no bigger! Please give me your thoughts!

Mike can you be more specific regarding room size showing windows, doors locations, etc? Is this a basement level or walkout, finished or unfinished, etc. Also, what shop tools do you need floor space for? The 20' x 30' indicate a large unfinished room but it would be helpful to understand more about its current use and location. Thanks, Dave

@darlander posted:Mike can you be more specific regarding room size showing windows, doors locations, etc? Is this a basement level or walkout, finished or unfinished, etc. Also, what shop tools do you need floor space for? The 20' x 30' indicate a large unfinished room but it would be helpful to understand more about its current use and location. Thanks, Dave

Hi Dave, the CEO says no trains in the basement, that's why we got the 20' X 30' shop. Right now it has a wall across the back of it to make a 10' X 20' room and the rest is open shop. My plan is to move it out to 20' , which would leave me a 10' X 20'w work shop area with a 16' roll up door.

I will try and get on SCARM tomorrow to draw something up from memory.

@trestleking posted:

I really like the open grid method you're using! Gives you many options to vary elevations and provide unique scenic detail. Good luck with your project!

Cheers, Dave

Picked up some freight cars, "like what was I thinking".... Anyway, got two of them pretty well 3 rail scaled in a couple of days.

One was the MTH Premier flat car with the Sebewaing Beer pup trailers, then 2 Lionel Round Roof boxcars.

Stripped all the trailer deck hardware off the flat car as I wanted the trailers for my industrial area where I have a beverage warehouse. Lowered it by at least 1/4", filled the holes, and did more scribing on the plastic wood grain deck before weathering.

To lower it, I cut off the MTH "top hat" stand offs that raise it to ridiculous levels, then bored out the hole to accomodate a washer, and used a Forstner Flat bottom bit 3/4" diameter to make room for a second re-inforcing washer. Photos below for anyone interested.

The Lionel RR boxcar has been dull coated, weathered with Pan Pastels on 1/2 the car. Figured I'd review some photos before I weather the other side.