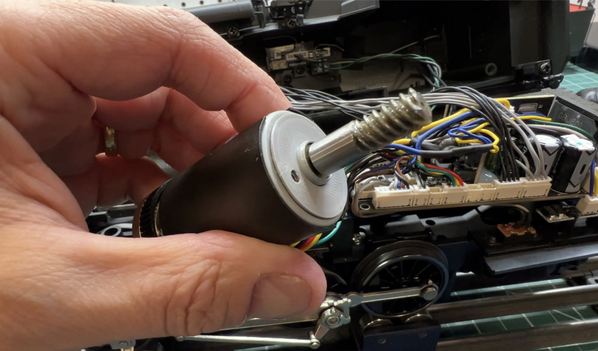

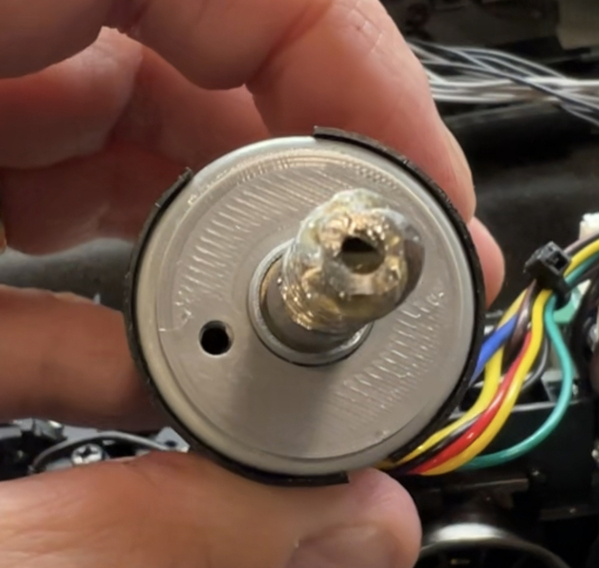

Glad to hear this worked. Shimming the motor is a bit easier than slotting the cover. The motor being pulled into the gearbox in reverse helps explain how the failure only happens in reverse, at least in my examples. This is what led to my suspicion of there being a thrust issue vs. an engagement problem.

When I first got the 1369 it couldn't even back a 20-something car train without locking up. When it came back from Lionel, it would only lock when being stalled in reverse (which could occur if one of the rollers dropped into one of my #5s). Upon inspection I found that there is a shim on the gearbox top that may or may not have been there since the beginning, similar to earlier pics on this thread. I also found what appeared to be a thin washer that was cut in half and inserted under the two rear screws. Removing the shim/washers would cause the gearbox to be too tight in mesh, adding more shims would cause the gears to not engage well (was also noisy).

I still think Lionel meant well with this design whether it's this direct drive style or the Canon type. When set up correctly it has very little friction and lash. Back-drivable seems to be a byproduct of this effort according to some but think of it this way - your locomotives experience 'back-drive' more commonly in other situations that doesn't involve you pushing your engine around by hand. Running a heavy train downhill and/or decelerating rapidly can put a back load into the drivetrain. More commonly back drive would come from other engines involved in lashups.

In any case, all's well that ends well.