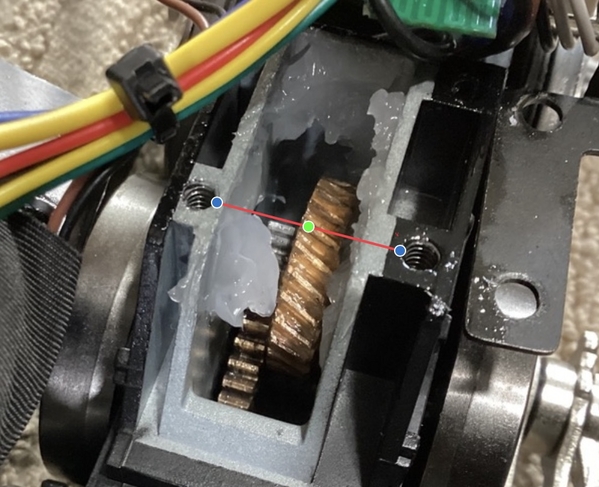

Testing is still ongoing, but I’ll share some findings as I go along, ….So I’ve dyed the gears, and ran a pattern, although the worm wheel is offset, the worm shaft does make decent contact. It’s a pretty fat worm shaft, and it does make up for some of the offset, ….The next thing I looked at is the clear plastic shim between the gear box and the motor mount. On the test rollers, with all the boards unplugged from the motor I was able to duplicate the issue in reverse with very low voltage DC. Moving in reverse, I was able to observe the jerky motion and every once in a while I could get it to “catch” and stop,….the slightest help on the flywheel and it would move again, …..I don’t think I was even at 100 rpm even,…..so we’re talking oober slow motion……..I tried removing the shim which BTW is a whopping .3 mm thick clear piece of like window plastic, but without the shim, the gears are bottoming out and locking up before I could snug the first screw. As a test, I made a new shim from .5 mm styrene sheet. This was a huge improvement in reverse!!…all the jerkiness went away, there was no noise, and I couldn’t force it into a lock up,…. But, ….forward still has the gear noise…..so still some studying needed,….

Pat