The final solution, forget the stuff below!

****************************************************************

Edit: This is a link to the latest and greatest version with the 555 timer that requires no calibration.

Build files for 555 timer version

****************************************************************

*** Back to our regularly scheduled discussion. ***

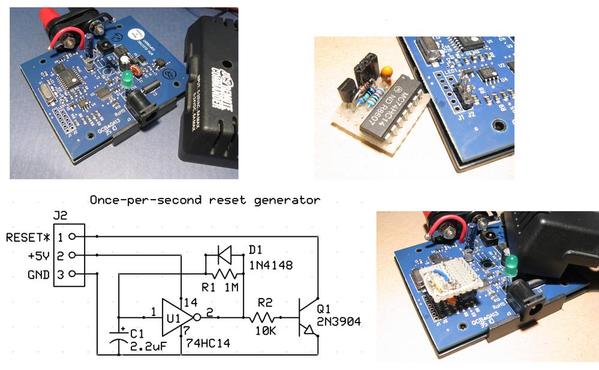

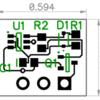

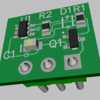

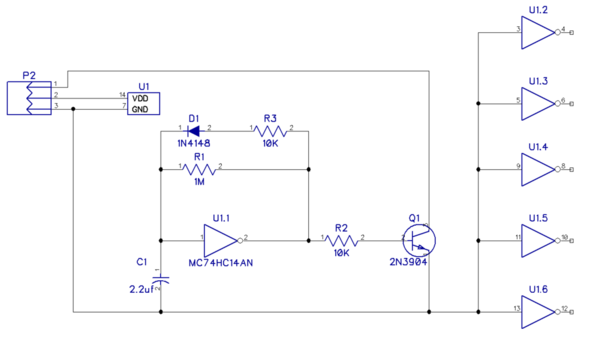

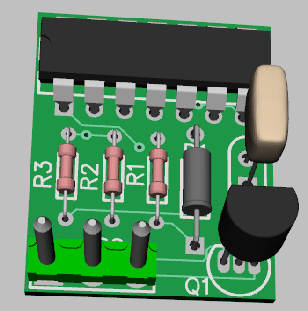

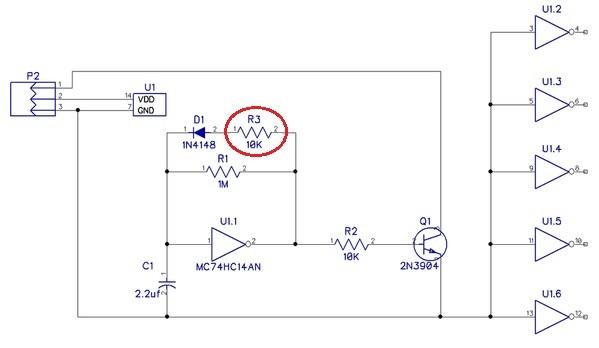

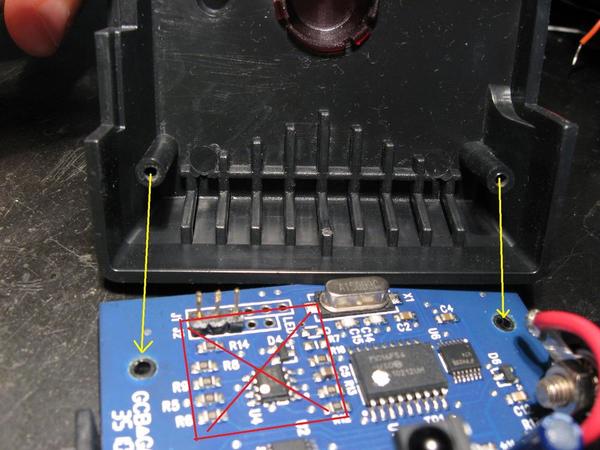

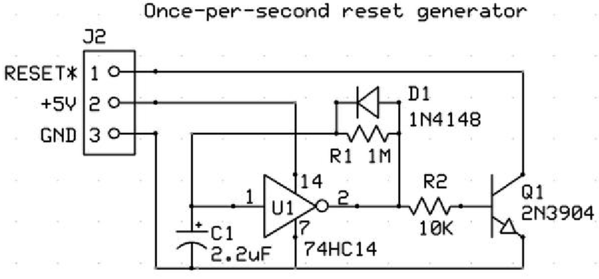

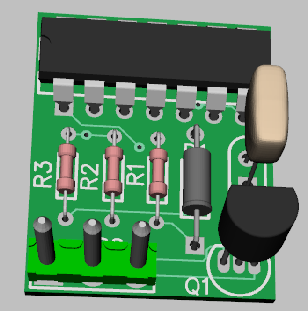

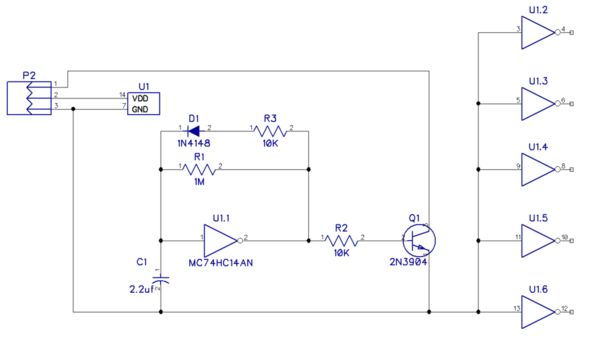

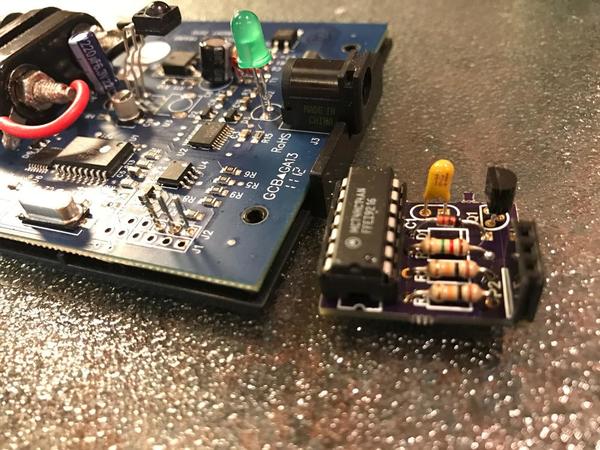

This is the what we finally came up with. It's a small add-in board to a DCS Remote Commander that turns the DCS-RC into a continuous watchdog generator. It plugs into some pins we add to the PCB.

DCS-RC Watchdog Reset Generator Thru-Hole Gerber Files.zip

================================================================================

Where we started

================================================================================

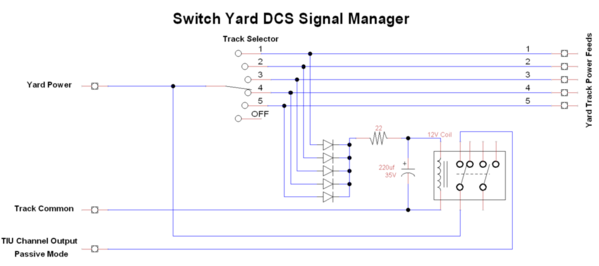

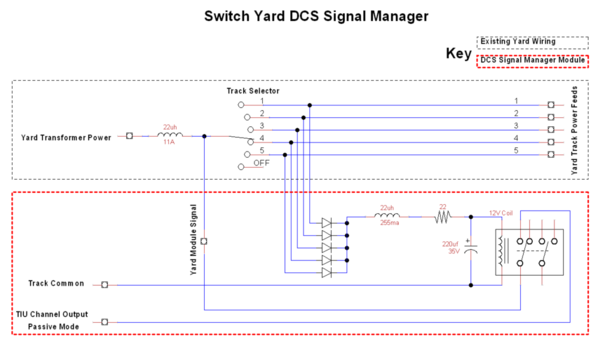

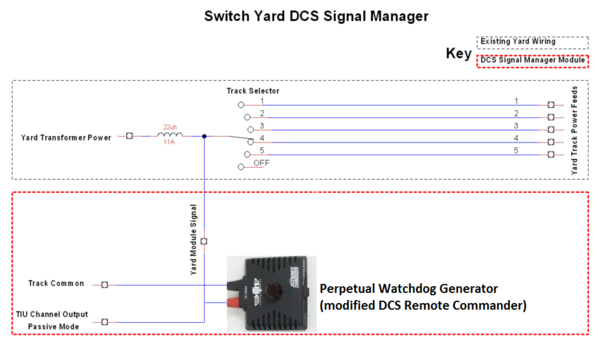

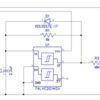

I'm working on coming up with a solution for some yard track at our club, we have several sets of tracks that we'd like to get DCS working on. We have a rotary switch to select one of "n" tracks to power at a time, so I came up with this scheme.

We will be using a separate TIU channel for this task, and it'll be used in passive mode. The yard power comes through a high-current 22uh choke to avoid any issues with crosstalk with the DCS signal on the mainline. Operation is as follows.

Starting with the Track Selector off, no power to the TIU channel or tracks. Switch is rotated to the correct track, the relay is energized, and that track is connected to the TIU channel output. This results in the DCS signal becoming active and emitting the watchdog. The plan is to keep the engine silent until it's started up.

See any issue with the idea? Got any suggestions to improve on it?