Originally Posted by Texas Pete:

I like to start with a molehill...

Pete

A geez, someone else does it like me!

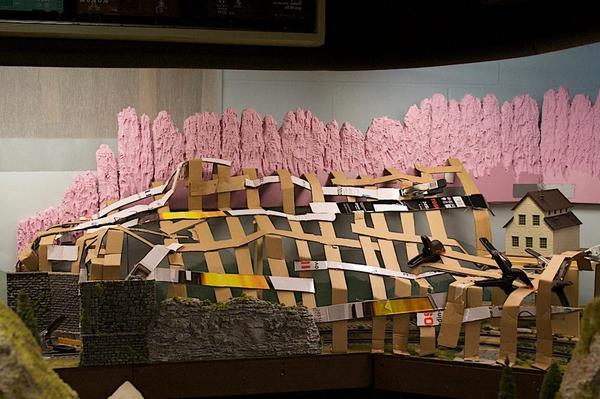

I build profiles of the mountain out of 1/2 plywood, spaced about every -five six inches, standing up, basically at this point, I have a set of parallel crossections of the mountain I want, .

I then glue small sticks - think Popsicle sticks but I use wood strips bought from model expo or scrapes, often, at 90 deg angles, one tip on one profile, the other on another, across and between the tops of the crossections, connecting them. I space these popsicle sticks about every 1/2 inch. When I finish, the mountain's rough crossection is outlined in "Popsicle sticks."

I let the glue dry a day. Then cover the whole thing with several layers of grocery paper bag (just thick brown paper will do). I cut it into strips ten inches long by one and one half wide, and I soak each piece briefly in a 15% wood glue/85% water mixture and stretch the pieces out over everything, covering the entire "mountain" in several layers, fully..

I let that dry and then smear spackling paste over the whole thing, using a folded wet paper towel to smooth the surface or add some rough details, maybe scratching in lines for strata on rock faces, etc.

it dries overnight. I prime and paint it, then do the scenery grass and brush and trees, etc.