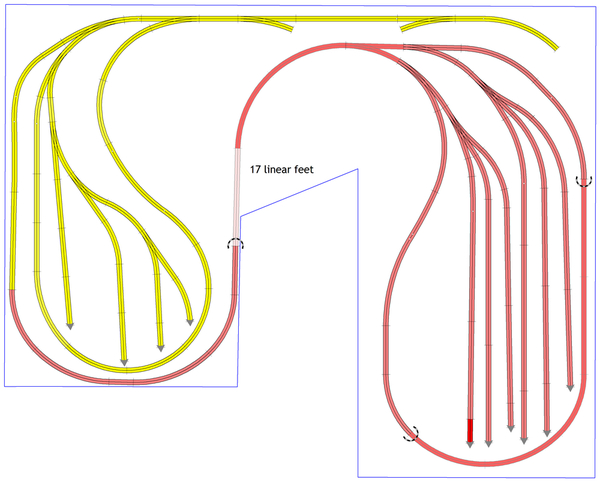

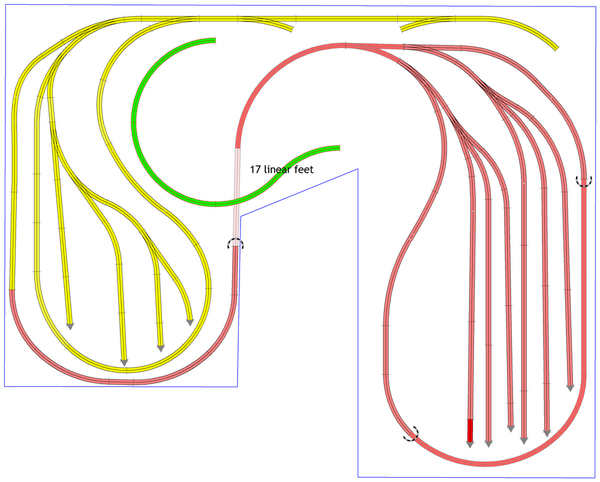

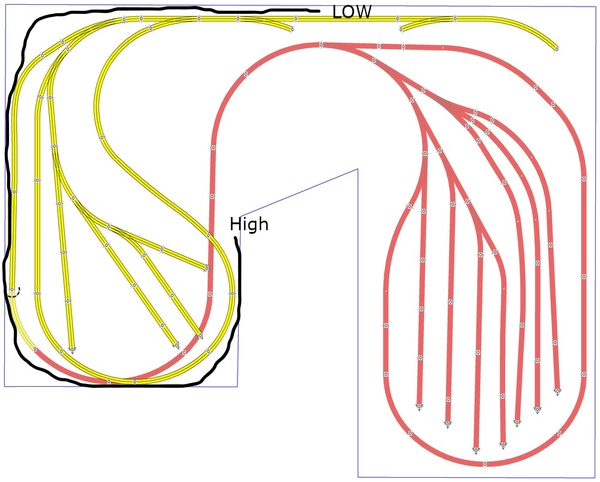

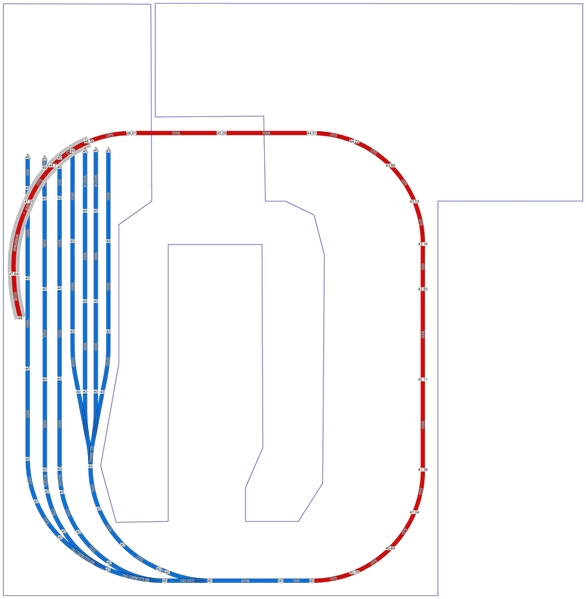

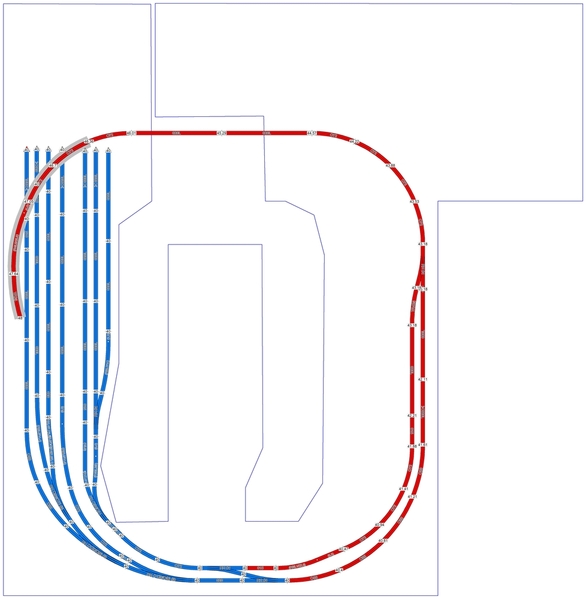

@ScoutingDad posted:Bob, as I recall your space is tight. I like the run around approach. I suggest you look at running the red track exiting the yard along the back and then down the left side. Use that track length to make the climb to the next level. Even at a 4% grade you would need 14 1/2 feet plus the transitions. I think you have that length on those two sides. Mine is complicated by the 72 dia curves with the parallel main at 88 dia.

The base dimensions are 8' (left), 12' (top), and 10' (right) so I should have the run length I need. Getting the vertical clearance under the main level where the red intersects the yellow in time would be the biggest challenge. It may not be possible without shortening the yellow loop to allow the red more running length to transition down.