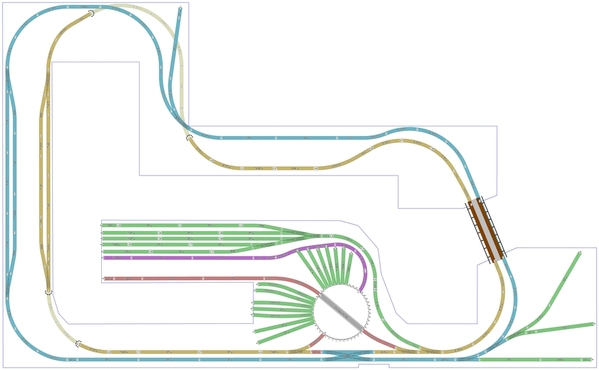

Ok, John, here's what I come up with using 25'. I added some preliminary trackage just to get an idea what will fit. The bench work is all 30" reach. Ignore the 16'7" and note that it doesn't watch the yellow area.

|

|

@Mark Boyce posted:John, you just gained some space; well not really, but will help on design!

Hi Mark, Yes I understand your comment clearly. I need all the help I can get on design.

Thanks for the support

@DoubleDAZ posted:

Hi Dave,

Looks great! I will fix the yellow area's as they are off and were onl a general guidline which makes it confusing to sa the least. On the bottom/north wall there is a 4" bump out 18' from the east wall. The bump out is 19" long It looks like the yellow hide that feature. I'll make corrections and repost.

Again thanks for your help!

John

Mark, I understand exactly what you are saying. I need all the help I can get with design, even if it already existed. ![]()

Thanks John

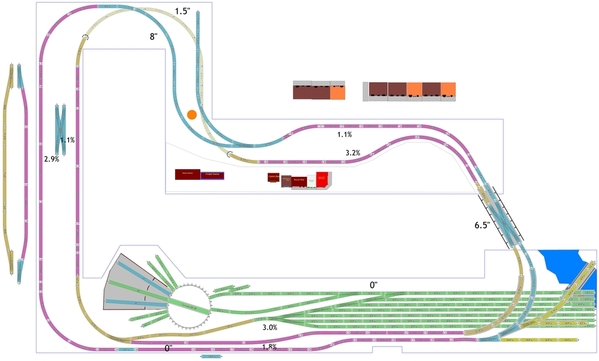

Dave here is a better/accurate view of room with all its nuances. Can you post your design in scarm? And it appears there is opportunity for some bump outs to add scenery and spurs.

Thanks in Advance

John

John, here's your file with my additions on a separate layer (DAZ).

I've also included a view without all the extra room stuff that's not applicable to the work space for the layout. Note the changes to the Red baseboard outline. I added 2 peninsulas, each 5'x5' with 30" aisles. I haven't played with tracks yet, but I'd probably add a lift-out bridge at the top to connect the peninsulas. This was just to show a different way of looking at the space, be able to use O72 curves throughout and have access when needed without using access hatches. Note that my Green area differs slightly from your Yellow area on the right side.

Hi Dave,

Thanks for cleaning it up and using proper alignment. Huge help! I would like to have my double track Atlas Pratt Bridge used between the two peninsulas, I was planning to hinge one side and lift the other side vertical for passage to the central area. Now to start implementing track, industry and towns. Looking for a coaling operation, as main industry along with towns, freight etc. As far as track goes, at least one continuous loop with reverse loops and then sidings, spurs for pick ups and deliveries. possible small yard for storing trains. So I am probably looking at a 40' x 60' area which is not available... ![]() But I am extremely happy with the space I do have and will enjoy it all!

But I am extremely happy with the space I do have and will enjoy it all!

Again Thanks for all the help!

John

Hi Dave,

Your fiddling is more like a concert. Love the peninsula and the yard it affords. Looks like the round house gives the reverse options too. I do have a ross double crossover switch which could do the cross over between the two main lines at the north wall.

This is more than exciting, to see the space being used so cleverly.

Thanks

John

John, Dave really came up with some great ideas for all 4 of my plans before I settled on this one. You can tell he likes what he is doing with the plans. Dave fiddles as fast as Charlie Daniels did with the fiddle!! I like what you came up with too, Dave.

Thanks Mark. Got tired of watching too much of The Handmaid’s Tale and there’s not much else on. I finished packing the car early for our road trip to Gainesville GA for Labor Day week, so why not play with some designs on a sweet Sunday afternoon? BTW, I liked the fiddle analogy. 🤪

That’s quite a road trip, Dave! I’m glad you folks are able to get back to some traveling again!

Haven’t been anywhere since June 2019. Usually we’d have gone somewhere in September/October, Cocoa Beach FL in February, Gainesville in April and we had an extensive trip planned for this month up to the Vancouver area, over to the Calgary area and maybe all the way to Thunder Bay ON. COVID19 has really put a damper on our travels and it stinks. 😡

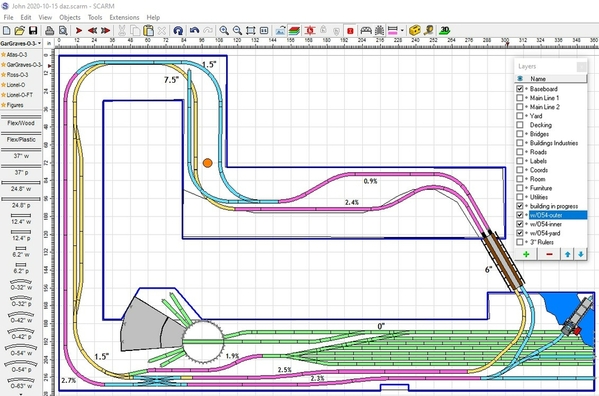

Here is an attempt at a workable layout, which i am not sure it really is workable. It looks like it eeds some elevation changes with over/under tracks. Hoping to fit in some industries (maybe left/below bridge) which is a lift bridge for passage to the center. Please ALL comments are more than welcome. I do like the idea of the turn table and maybe add a 3 stall engine house. ![]() Not totally happy with yard yet as it seems to take a lot of room and track maybe too close for actual operation.

Not totally happy with yard yet as it seems to take a lot of room and track maybe too close for actual operation.

Have been working on the room and have painted new wall a "sky blue" Now looking at overhead lighting. There are two air ducts running down that ceiling area that I found some Led fixtures would fit in the space between the parallel ducts. Now I need to make some mounting brackets and see how they look and the quality of light they give from that position.

John, The plan looks like a good start. I'll leave suggestions for the yard and turntable area for others, since I never had the space to do either. Are you planning to use a double track bridge for the walkthrough opening on the right? It would be easier than bridges on two levels like I have. That means the grade from there to the first overpass would be pretty steep, though my 4% grades are manageable for the short trains I'll run. I'm thinking Dave is away on his trip to Georgia about now, so I don't know when he will be able to look at it. I never did get figured out how to setup grades on SCARM. He did it for me.

The blue walls look great! Yes some lighting around those ducts would help a lot. Are you going to leave the ceilings open, that is no drop ceiling? I see a lot of people who do that paint all the joists black so they aren't so noticable and it keeps the dust to a manageable level. I left my floor bare concrete. Are you going to do the same, or put in some floor covering? I may do something in the future, like the interlocking rubber mats in the walking area, but there is only so much money to work with.

Mark,

There are already grades of 3.4% and 3.6%, so I'm not sure what John is saying. The Blue tracks are at 7" elevation and the yellow tracks on the left are at 1" elevation for a 6" separation.

The TT is a 34" model with crazy curved 37" whiskers done with flex track on the left and 19"-29" on the top". With a 34" TT, there's no way to fit a Round House because it has a 60"-63" footprint from the center of TT to the back wall of the RH, assuming that large engines will have to fit. The last photo is a view of the original TT configuration I sent John earlier. He moved the double cross and went lower with the elevation change. Going lower is something I always seem to forget. ![]()

Well Dave, those grade numbers sound very familiar to me. Going lower is something I forget too. For some reason I have found getting my vertical easements at the top and bottom of my grades muh harder to do than when I built HO and N layouts.

I knew there needed to be a runaround track at the yard, and the tail track too. Maybe John could fit in a rectangular two-stall enginehouse in like I have.

Mark, I shouldn’t have said no RH, depends on what he wants and how to build it.

Agreed, I'm shoehorning in more than I thought I could as construction progresses. Maybe a roundhouse could be squeezed in somehow.

@Mark Boyce posted:John, The plan looks like a good start. I'll leave suggestions for the yard and turntable area for others, since I never had the space to do either. Are you planning to use a double track bridge for the walkthrough opening on the right? It would be easier than bridges on two levels like I have. That means the grade from there to the first overpass would be pretty steep, though my 4% grades are manageable for the short trains I'll run. I'm thinking Dave is away on his trip to Georgia about now, so I don't know when he will be able to look at it. I never did get figured out how to setup grades on SCARM. He did it for me.

The blue walls look great! Yes some lighting around those ducts would help a lot. Are you going to leave the ceilings open, that is no drop ceiling? I see a lot of people who do that paint all the joists black so they aren't so noticable and it keeps the dust to a manageable level. I left my floor bare concrete. Are you going to do the same, or put in some floor covering? I may do something in the future, like the interlocking rubber mats in the walking area, but there is only so much money to work with.

Hi Mark, The bridge is a double track atlas Pratt truss bridge. I am hoping to have it hinged on one end and swing up. In that area is a steel overhead I-beam which lowers that part of the ceiling clearance. So positioning the bridge maybe determined by clearances. Which leads into the question off drop ceiling or black paint or other suggestions. I realize that this decision needs to be made sooner rather than later.

The blue paint was picked out by my artistic wife, so all credit goes to her. She also picked out the floor paint which I am starting to paint now. I was also thinking about the interlocking floor pads, which will wait until I see if their is any funds left at the end of the build. Lighting is costing more than I anticipated, as I am sure other things will go over budget too!

Thanks for the feedback

@DoubleDAZ posted:Mark,

There are already grades of 3.4% and 3.6%, so I'm not sure what John is saying. The Blue tracks are at 7" elevation and the yellow tracks on the left are at 1" elevation for a 6" separation.

The TT is a 34" model with crazy curved 37" whiskers done with flex track on the left and 19"-29" on the top". With a 34" TT, there's no way to fit a Round House because it has a 60"-63" footprint from the center of TT to the back wall of the RH, assuming that large engines will have to fit. The last photo is a view of the original TT configuration I sent John earlier. He moved the double cross and went lower with the elevation change. Going lower is something I always seem to forget.

Hi Dave, I'm looking at having some height changes in track to add interest with trains running over and under each other. I made some poor attempts with setting a high elevation of seven inches and a lower one inch which may not be needed for clearences. Thought using a worst case would be better to see if there was a grade bigger than four degrees. I moved the double crossover to provide a lower grade. The turntable and track coming off of it was to see how much room there is for an engine house or a small round house. Also was trying to keep in mind space for industries and towns. I loved your putting in the turntable and that area. I have a ross four way hard switch that I would like to use which is why I changed any of your original hard drawing. Almost forgot I have a vascular bridge and a MTH 30" grider bridge that I would like to work in somehow.

Thanks John

@Aegis21 posted:Hi Mark, The bridge is a double track atlas Pratt truss bridge. I am hoping to have it hinged on one end and swing up. In that area is a steel overhead I-beam which lowers that part of the ceiling clearance. So positioning the bridge maybe determined by clearances. Which leads into the question off drop ceiling or black paint or other suggestions. I realize that this decision needs to be made sooner rather than later.

The blue paint was picked out by my artistic wife, so all credit goes to her. She also picked out the floor paint which I am starting to paint now. I was also thinking about the interlocking floor pads, which will wait until I see if there's any funds left at the end of the build. Lighting is costing more than I anticipated, as I am sure other things will go over budget too!

Thanks for the feedback

I know about funds. I still want to put up one more set of lights. I can work that from my aisle, but need to do it before I put in any scenery. Since this is the first "permanent" O gauge layout I have built, I am astounded at how track and switches costs add up compared to HO or N scales. I wouldn't be able to afford to build even a medium sized layout if I had the space to do it.

@Aegis21 posted:Here is an attempt at a workable layout, which i am not sure it really is workable. It looks like it eeds some elevation changes with over/under tracks. Hoping to fit in some industries (maybe left/below bridge) which is a lift bridge for passage to the center. Please ALL comments are more than welcome. I do like the idea of the turn table and maybe add a 3 stall engine house.

Not totally happy with yard yet as it seems to take a lot of room and track maybe too close for actual operation.

I went from an N scale layout to O scale and I had planned on having a six track yard. Well...that did not work. O scale yards take a lot of room but I would recommend to have a yard (even a small yard) because it gives you a spot to keep a train ready to go and it is still on your layout.

I have been through that and I agree, Dan!

John, I think you saw this, but I'm splitting my enginehouse and yard between separate levels. When there isn't much room, it's better than nothing.

Aegis21:

Although I joined this thread later on, I wanted to commend your process for planning and gathering input for an L-shaped layout. I designed and built an L-shaped layout in an addition to the rear of our house, which was created as a home office by the previous owner - a draftsman. Now it's my train room! Not as BIG as your space, so I'm envious!

I used ANYRAIL to design my layout. Quick to learn, easy to use.

I provided aisle space around the perimeter of most of the layout; with 20/20 hindsight, I now consider it "wasted space." I should have installed an around-the-wall layout as you intend to do. To gain more trackage, I installed a second level. It contains 36 DEPT 56 North Pole Village porcelain buildings and three short point to point trolley lines. Two of the trolleys and a handcar have Christmas decor.

The E-W main platform is an oval with a figure 8 built-in, so I have four reversing loops in that design. The sidings and an industrial district are in the N-S leg of the layout, which also includes a DINOSAUR PARK for playtime fun for my young great grandson, Matthew (now age 7). Pix attached.

Your initial post to the OGR FORUM gathered many helpful follow-up notes. Carry on, relentlessly ...

Mike Mottler LCCA 12394

mottlermike10@gmail.com

@Mark Boyce posted:I know about funds. I still want to put up one more set of lights. I can work that from my aisle, but need to do it before I put in any scenery. Since this is the first "permanent" O gauge layout I have built, I am astounded at how track and switches costs add up compared to HO or N scales. I wouldn't be able to afford to build even a medium sized layout if I had the space to do it.

Yes Mark, this is not a poor man's hobby, although I've never had a hobby that was free! I have been collecting train stuff over the past years and that has helped spread the burden on the bottom line.

@dan 77 posted:I went from an N scale layout to O scale and I had planned on having a six track yard. Well...that did not work. O scale yards take a lot of room but I would recommend to have a yard (even a small yard) because it gives you a spot to keep a train ready to go and it is still on your layout.

I am sure this is good advice and will make every effort to do something along those lines. Thanks for the words of wisdom.

@Mark Boyce posted:I have been through that and I agree, Dan!

John, I think you saw this, but I'm splitting my enginehouse and yard between separate levels. When there isn't much room, it's better than nothing.

Mark I did see your pics and love what you have done in tight quarters. Amazing and inspiring for sure!

@Mike H Mottler posted:Aegis21:

Although I joined this thread later on, I wanted to commend your process for planning and gathering input for an L-shaped layout. I designed and built an L-shaped layout in an addition to the rear of our house, which was created as a home office by the previous owner - a draftsman. Now it's my train room! Not as BIG as your space, so I'm envious!

I used ANYRAIL to design my layout. Quick to learn, easy to use.

I provided aisle space around the perimeter of most of the layout; with 20/20 hindsight, I now consider it "wasted space." I should have installed an around-the-wall layout as you intend to do. To gain more trackage, I installed a second level. It contains 36 DEPT 56 North Pole Village porcelain buildings and three short point to point trolley lines. Two of the trolleys and a handcar have Christmas decor.

The E-W main platform is an oval with a figure 8 built-in, so I have four reversing loops in that design. The sidings and an industrial district are in the N-S leg of the layout, which also includes a DINOSAUR PARK for playtime fun for my young great grandson, Matthew (now age 7). Pix attached.

Your initial post to the OGR FORUM gathered many helpful follow-up notes. Carry on, relentlessly ...

Mike Mottler LCCA 12394

mottlermike10@gmail.comMike I was looking at a perimeter aisle and would have still left that door open until your advise. Second level looks great and will consider doing that to increase acreage

Thanks and nice pics, get your great grandson smiles a lot!

Mark, You have been so inventive to make the utmost of your space and railroad. Great having a yard and engine house on your layout! I am still trying to visualize industries and town(s) (space allowing). I super sized the turntable area and that will have me use an overhead creeper in that area,which may be a price I'm willing to pay. This option appears to provide a lot of user interest and railroad flexibility.

Off the turntable I am contemplating a 3 or 4 stall round house. I think it could squeeze in and would add a lot to that area. Still having trouble locating a spot for my bascule bridge, town and the long back straight run with one or two sidings and should there be some curves and elevation changes for interest. I'd like the bascule bridge to be over a river that empties into a body of saltwater. Just a nostalgia thing for me.

How is your layout coming? Can't wait to see what you are doing. Hope all is well.

John, I agree if you really want the turntable and roundhouse, then the topside creeper is well worth the investment. I would love to have a turntable and roundhouse, but in my space there wouldn't be room for much else. ![]()

I think I needed to see the layout in actual three dimensions before I could see how to fit in the wye, two-stall engine house, and yard below. If you go waaayyy back in my design and build topic, you can see how all were discussed in some measure during previous plans. It all started in January 2017! Wow, it has been that long to get this far. I call this plan that I am building Plan D. Plan A was scrapped on the drawing board. I started construction on Plans B and C, then I tore them apart and repurposed everything in Plan D. I am going to have a good bit of track and a few switches left over when the track is all done. So the inventiveness was more like Thomas Edison finding 1000 ways that don't work before one does. ![]()

I have been taking advantage of the warm but not hot weather trying to get some things done outside that I didn't get done in the summer or last summer before the knee replacement. Therefore I haven't had much to report on construction. In the evenings I did fiddle with trying to add another siding that didn't work a couple places, but I think I have found a place to fit it in.

I like the bottom plan with the two passing sidings, one on the yellow and one on the blue track. For me, elevation changes are hard enough to just get a steady grade with verticale easements at the top and bottom so I could cross over the other track, that I don't want to think of building the slight ups and downs like in reality. Making long straight stretches look better with some slight curves really looks great. Then again, I have enough trouble bending flex track to suit a small connection, that I didn't attempt the slight curvatures. Maybe you could do it on your much longer straight-aways with the largest diameter curved sections on the market.

Maybe the bascule bridge would work on the yellow track across the aisle from the yard. It would be great if you can fit it and some kind of saltwater in considering where you grew up.

I'm hoping to get something posted on my newest siding, but so far there isn't much to photograph. I hope someone else throws out some ideas on your plan and comments.

Well Mark you have a good eye then as your layout is coming along with great additions! How is your knee doing?

Yeah the trouble I am having with the bascule bridge is the twin main lines, needed a double track bridge lol.

Thanks for the suggestion on the largest curves to add some interest and break up the long straight ways !

John, My knee is doing pretty well. How is yours?

New knee really good the other, is bearable. Thanks for asking.

Ok, so progress up until now has been slow and unsteady. Finally the room is coming together, as in the walls and floor are painted. Lighting is being developed and in progress. Now if I had a better idea of my layout, things would be on the optimistic side of full speed ahead. I have read many post about my first question... Layout height! What is the overall range of heights. My gut instinct is 42" high. Range starting around 38" to 42" anyone with reasons to go to a different height? I am sure the lower the height, the more accessible the car corners are to reach.

next question, does anyone have instructions for making scenery on L-girder benchwork? Looks like lots of open holes to fill...

All help is greatly appreciated!

Thanks John

My 2 cents regarding layout height... One portion of my layout is at about mid-chest (around the top of the strike zone). This shortens my useful reach, but it also makes it easy to sit on a rolling stool underneath to work on wiring and gives a more interesting viewing perspective. It might also be a bit high if being viewable by small children was a consideration. The other portion is about waist high - easier to work on from above, but I need to work on my back on a creeper to do things underneath, which I don't enjoy.

When I do it over, I'm not sure which way I'll go.

It's a personal decision based on reach, mobility, and preferred viewing angle. Perhaps it would be useful to set up a table with some trains on it and raise/lower the height and see what works best for you.

Re scenery on L-girder benchwork... Mine is L-girder (quick, strong, uses less wood), but I haven't yet done any scenery on it. However, I laid plywood over it, so there are no holes to fill unless I create them. If you don't go the plywood route, it seems like gaps can be filled with thin plywood or rigid foam panels.

My plan has been to build raised areas using foam, and cut openings where depressions are needed. Sadly, due to inertia I can't report on how well that is working out. ![]()

@Mallard4468 posted:My 2 cents regarding layout height... One portion of my layout is at about mid-chest (around the top of the strike zone). This shortens my useful reach, but it also makes it easy to sit on a rolling stool underneath to work on wiring and gives a more interesting viewing perspective. It might also be a bit high if being viewable by small children was a consideration. The other portion is about waist high - easier to work on from above, but I need to work on my back on a creeper to do things underneath, which I don't enjoy.

When I do it over, I'm not sure which way I'll go.

It's a personal decision based on reach, mobility, and preferred viewing angle. Perhaps it would be useful to set up a table with some trains on it and raise/lower the height and see what works best for you.

Thank you for the input, I like the idea of setting up a table and adjusting the height with some trains on top. Reach is hopefully a secondary consideration as I am looking at an overhead creeper. I am 6' tall and working below decks is more of a concern as it will be a hard hat area for sure.

Again Thanks for the suggestions!

John

@Mallard4468 posted:Re scenery on L-girder benchwork... Mine is L-girder (quick, strong, uses less wood), but I haven't yet done any scenery on it. However, I laid plywood over it, so there are no holes to fill unless I create them. If you don't go the plywood route, it seems like gaps can be filled with thin plywood or rigid foam panels.

My plan has been to build raised areas using foam, and cut openings where depressions are needed. Sadly, due to inertia I can't report on how well that is working out.

I do like the idea of elevation changes that L-Girder allows and it is good to hear your experience has been positive, especially the quick and strong part. Am leaning towards foam for mountains and hills with maybe using it as a base covering so it can be "dugout" for small streams etc.

Thanks

John

John, My current layout is 43" high with the highest track level at 50". I am 5' 11", and it works out well for me. My last layout, which was a long time ago, used L-girder. Places that didn't have roadbed and track were covered by extruded styrofoam which was the base for all my scenery. It worked out well. I didn't have any heavy buildings, but if I did, I would have built plywood bases to support their weight.

I used the method of setting up a temporary table with cardboard boxes to represent different heights before building that last layout which was a little higher. This time, I just winged it from memory not wanting it quite so high. Our girls were little then, and I had to hold them up to see the layout. (Shows how long ago it was-the youngest is now 27). Since we don't have any grandchildren, I decided to build this layout to suit me, and will do whatever when the time comes that we have grandchildren. I know my wife will give me space for age appropriate trains if the time comes.

Mallard is right on for determining decking height. The number of inches is not important because all of us are different heights. A shorter person might go as low as 36” while a taller person might go as high as 48” or even more. Some like to view from chest high while others like to view while sitting down. Children and grandchildren can be accommodated with something like a step stool. Those who add a 2nd level or elevated track have to consider that too.

As we age, we also have to think about access from below. If you plan traditional L-girder, note that it adds to the depth of the benchwork. With tabletop style benchwork you have your 1x4 frame topped with plywood/Homasote, so you end up closer to 5” (3.5+.75+.5). However, L-girder adds another 1x4 layer. It has the L-shaped rails for another 4.25”, then the girders, then the plywood/Homasote, around 9” total. That doesn’t sound like much until you’re on your knees crawling underneath to deal with wiring.

I’m not sure what you mean by “holes to fill”, but I’ll assume it’s open style decking. L-girder is just the framing. Like Mallard did, you can still lay plywood on top of it for a full deck. The other option is open cookie-cutter where you just put decking under the tracks and then fill in the open spaces with landscaping. That can be done with plywood/rigid foam panels or other materials to form mountains, etc. Like the track, it’s all supported by the joists or with risers. Here’s a crude example. Note that it has supports for the legs that I didn’t count in the 9” depth, the L-girder rails, the joists and then the full panel decking. In this case it looks like an 8’ section with only 1 center joist vs multiples on 16” centers. If you look at the 2nd photo you’ll see all the parts of benchwork using L-girder as the framing. It shows all the various types of risers, cleats, etc., used to support both open style roadbed and full sheet roadbed. Open style is mostly used where there are a lot of elevation changes throughout the layout. Where that isn’t the case, like yards, full panel is used. When you do open style, you simply cut the section for track out and raise it with risers. You then raise/lower the rest to get the look you want. You can leave it on the joists and fill in with rigid foam and other materials to create rolling hills, etc.

@Aegis21 posted:...Reach is hopefully a secondary consideration as I am looking at an overhead creeper....

If possible, I'd suggest trying a topside creeper if you know someone who has one. Also, there are other threads on here regarding them - suggest searching for them and reading. I own one - there are many pluses and minuses, and a lot of it depends on one's agility and the ability to move it around the layout (the base has long and angled legs). Although it's an indispensable tool, it can be awkward and uncomfortable to use - it's definitely a "last resort" method, at least for me. It's also hard to store - you can't easily break it down or fold it up.

It looks like a lot of your plan is around the walls, so you might be able to get by without one.

@Mark Boyce posted:John, My current layout is 43" high with the highest track level at 50". I am 5' 11", and it works out well for me. My last layout, which was a long time ago, used L-girder. Places that didn't have roadbed and track were covered by extruded styrofoam which was the base for all my scenery. It worked out well. I didn't have any heavy buildings, but if I did, I would have built plywood bases to support their weight.

I used the method of setting up a temporary table with cardboard boxes to represent different heights before building that last layout which was a little higher. This time, I just winged it from memory not wanting it quite so high. Our girls were little then, and I had to hold them up to see the layout. (Shows how long ago it was-the youngest is now 27). Since we don't have any grandchildren, I decided to build this layout to suit me, and will do whatever when the time comes that we have grandchildren. I know my wife will give me space for age appropriate trains if the time comes.

I will follow up on the different height tables, there is an old work bench I could use for a temp height test. Thanks for a good starting point.

@DoubleDAZ posted:Mallard is right on for determining decking height. The number of inches is not important because all of us are different heights. A shorter person might go as low as 36” while a taller person might go as high as 48” or even more. Some like to view from chest high while others like to view while sitting down. Children and grandchildren can be accommodated with something like a step stool. Those who add a 2nd level or elevated track have to consider that too.

As we age, we also have to think about access from below. If you plan traditional L-girder, note that it adds to the depth of the benchwork. With tabletop style benchwork you have your 1x4 frame topped with plywood/Homasote, so you end up closer to 5” (3.5+.75+.5). However, L-girder adds another 1x4 layer. It has the L-shaped rails for another 4.25”, then the girders, then the plywood/Homasote, around 9” total. That doesn’t sound like much until you’re on your knees crawling underneath to deal with wiring.

I’m not sure what you mean by “holes to fill”, but I’ll assume it’s open style decking. L-girder is just the framing. Like Mallard did, you can still lay plywood on top of it for a full deck. The other option is open cookie-cutter where you just put decking under the tracks and then fill in the open spaces with landscaping. That can be done with plywood/rigid foam panels or other materials to form mountains, etc. Like the track, it’s all supported by the joists or with risers. Here’s a crude example. Note that it has supports for the legs that I didn’t count in the 9” depth, the L-girder rails, the joists and then the full panel decking. In this case it looks like an 8’ section with only 1 center joist vs multiples on 16” centers. If you look at the 2nd photo you’ll see all the parts of benchwork using L-girder as the framing. It shows all the various types of risers, cleats, etc., used to support both open style roadbed and full sheet roadbed. Open style is mostly used where there are a lot of elevation changes throughout the layout. Where that isn’t the case, like yards, full panel is used. When you do open style, you simply cut the section for track out and raise it with risers. You then raise/lower the rest to get the look you want. You can leave it on the joists and fill in with rigid foam and other materials to create rolling hills, etc.

Ah! Great explanation of combining different benchwork. So for the yard/roundhouse area flat benchmark and for areas with lots of vertical scenery L-girder can be used. Love the diagrams along with your insight.

I think that the turntable roundhouse area is too small for a 34" turntable. At the moment I do not own large locomotives however it could be a regret later on. Any toughts?

@Mallard4468 posted:If possible, I'd suggest trying a topside creeper if you know someone who has one. Also, there are other threads on here regarding them - suggest searching for them and reading. I own one - there are many pluses and minuses, and a lot of it depends on one's agility and the ability to move it around the layout (the base has long and angled legs). Although it's an indispensable tool, it can be awkward and uncomfortable to use - it's definitely a "last resort" method, at least for me. It's also hard to store - you can't easily break it down or fold it up.

It looks like a lot of your plan is around the walls, so you might be able to get by without one.

I have read a fair amount on this forum about topside creepers. And I can see they could be difficult at best, especially for long periods of time. The decision will be made after the benchwork has been started

Thanks for your insight

John,

Don’t confuse benchwork with the type of roadbed used. For the purposes of this discussion, there are 2 types of framing, one is L-girder and I’ll called the other “Standard”. There are also 2 types of roadbed, one is cookie-cutter and I’ll call the other “Tabletop”. You’ve seen photos of L-girder framing with cookie-cutter roadbed, so here’s one of Standard framing with cookie-cutter roadbed on risers. Note that the only difference is the type of framing to support the risers and roadbed.

Here’s a simple example of L-girder with both cookie-cutter and tabletop roadbed.

Here’s an example of Tabletop where they cut out sections they wanted to raise and supported them with risers. What’s underneath could be L-girder or Standard framing, it doesn’t matter.

There is no right or wrong way to do things, just as there is no right or wrong in what materials you decide to use, it’s whatever works for you.

@DoubleDAZ posted:John,

Don’t confuse benchwork with the type of roadbed used. For the purposes of this discussion, there are 2 types of framing, one is L-girder and I’ll called the other “Standard”. There are also 2 types of roadbed, one is cookie-cutter and I’ll call the other “Tabletop”. You’ve seen photos of L-girder framing with cookie-cutter roadbed, so here’s one of Standard framing with cookie-cutter roadbed on risers. Note that the only difference is the type of framing to support the risers and roadbed.

Here’s a simple example of L-girder with both cookie-cutter and tabletop roadbed.

Here’s an example of Tabletop where they cut out sections they wanted to raise and supported them with risers. What’s underneath could be L-girder or Standard framing, it doesn’t matter.

There is no right or wrong way to do things, just as there is no right or wrong in what materials you decide to use, it’s whatever works for you.

Beautiful bench work and great clarity on uses/flexibility! Looks like I will have to experiment and see what works best for my limited knowledge. Looks like a compromise between overhead access and underneath access. Since I do not have any experience with these situations, it will be my task to mock up a model bench work and evaluate the pros and cons of above and below clearances for my aching bones. LOL

Here is what I am leaning towards, for a track layout. Huge question is it realistic to have that turntable and yard as I have it now. Would like to have a roundhouse with three to five stalls. I am hoping with the use of flex track I can keep the distance between the round house and turntable to a minimum. I also changed the heights a bit to make the grades lower while maintaining vertical clearances. Any words of wisdom would be very much appreciated.

Thanks in Advance

John, I have never built or operated a yard of any size before, but I see usually folks suggest a runaround track for an engine to go around the yard ladder. I don't know if your yard as is would be difficult to switch or not.

John, here is a Millhouse Rivers 34" turntable with an extended 4-stall Altoona roundhouse overlay. As you can see, there appears to be room. However, you asked if the setup was realistic and the short answer is I don't believe it is.

AFAIK, there's nothing realistic about curved whisker tracks.

There's also nothing realistic about the long red track or the extreme curve of the long purple track. I can't figure out how you intend to use either one.

You have a 34" turntable feeding whisker tracks that are over 43" long. If you try to place whiskers that close to each other, you may need those 43" because engines need to be far enough back so the front ends clear each other as they move in and out. How many engines do you need to have on the layout at any given time?

The yard is basically limited to backing consists in since there is no way for engines to move around the yard and there are no lead tracks to work a consist without fouling the orange mainline. To really do that, you'll need to approach the bridge from the bottom, then back into the yard, drop the load, come back out, back onto the turntable, etc. If you want a switcher to do the work, you need to park the consist on the mainline and the switcher will have a really interesting job trying to break the consist apart and store the cars. The whole thing seems convoluted to me, but then I'm no expert on yard design.

@DoubleDAZ posted:John, here is a Millhouse Rivers 34" turntable with an extended 4-stall Altoona roundhouse overlay. As you can see, there appears to be room. However, you asked if the setup was realistic and the short answer is I don't believe it is.

AFAIK, there's nothing realistic about curved whisker tracks.

There's also nothing realistic about the long red track or the extreme curve of the long purple track. I can't figure out how you intend to use either one.

You have a 34" turntable feeding whisker tracks that are over 43" long. If you try to place whiskers that close to each other, you may need those 43" because engines need to be far enough back so the front ends clear each other as they move in and out. How many engines do you need to have on the layout at any given time?

The yard is basically limited to backing consists in since there is no way for engines to move around the yard and there are no lead tracks to work a consist without fouling the orange mainline. To really do that, you'll need to approach the bridge from the bottom, then back into the yard, drop the load, come back out, back onto the turntable, etc. If you want a switcher to do the work, you need to park the consist on the mainline and the switcher will have a really interesting job trying to break the consist apart and store the cars. The whole thing seems convoluted to me, but then I'm no expert on yard design.

Well Said Dave! I am throwing darts at a moving board blindfolded, for sure. The idea behind this drawing (and any others I have messed up) was simply, how much track can that area hold. I am learning as I go and you have been a great teacher, as you are direct and blunt which works for me. Just to give you an idea of any planning I may have put into this layout, The elevations were a high 7" to 1" to give a 6" clearing for overhead/under crossings. Just put that as the worst case and grades <4 shouldn't be an issue since I have a little wiggle room. The large 34" turntable is also along those lines of put in the biggest and if that has a chance then smaller would fit with less problems. To expound on my ignorance of train operations, I wasn't clear on the size turn table as it relates to engine size. Yes I understand the loco needs to fit on table without significant or any overhang. However does the tender also need to fit? Does an A/B diesel unit need to fit? When I say any and all help is welcome, I guess I really mean all help is required.

With that said, a turntable and roundhouse if at all possible would be fantastic, if it lends itself to overall operations. And an operating yard with a method to have a run around track, or other means of a switcher doing its job would also be appreciated. I do have a ross #170 four way yard switch, if that can be incorporated great, if not then that can be e-bay'd. Please feel free to give your opinion on any or all of these "wants" Also any one else please chime in as I am willing to learn and won't be offended by any remarks. This forum is a wealth of knowledge and I welcome any and all critiques.

John, You would want to turn both the locomotive and tender coupled together. It would could be a real pain to unhook some tenders from their locomotives, and I have never heard of it done before on the prototype or models. I think the same would hold for any AB units for similar reasons. I don't have an AB set out to see how long they are. Less tracks off the turntable would be good to eliminate the curved ones. The 4-way switch for the yard saves space, but then you would need a runaround track on each side of the yard. I have 4% grades on my layout, and they are working alright on my short trains. I'm sure you would like to run longer trains than I can. I setup a temporary track and tried it at different grades with each of my engines pulling cars to see what would work. Remember that it takes a little more pulling power on grades than straightaways.

John, I meant no offense. I’ve been assuming you’ve just been filling the space with track, but at some point you have to come back down to earth and work with something more realistic and, more importantly, something that will fit. 🤪 You now know a 4-stall Altoona roundhouse with 34” turntable will fit, so it’s time to build on that to see if a useful yard can be designed around it. Personally, I suspect you don’t need anything larger than the smaller turntables that are in the SCARM libraries. So many want to use the biggest turntable and biggest curves that they miss out on design possibilities smaller curves would allow.

Anyway, when it comes to fit, yes, the tender has to be included, though technically I suppose an engine alone could be pushed/pulled by another engine. Think about it though. If you push an engine onto the turntable, how will you get it into the roundhouse or onto a whisker track? A-B units would be the same, but don’t know if A-B units are even turned on a turntable. Many, if not most, yards have engine houses, not turntables and roundhouses. Also, there’s nothing wrong with having a turntable just to turn engines, it doesn’t have to include a roundhouse.

The yard is another story. You can have a storage yard, like what you have, to store multiple trains ready to be run or you can try to fit in a working yard where a switcher moves cars around to configure different trains. Obviously, a working yard requires more than just storage tracks and I don’t know that you have the space for both a turntable/roundhouse and a working yard, at least not where they are now.

@Mark Boyce posted:John, You would want to turn both the locomotive and tender coupled together. It would could be a real pain to unhook some tenders from their locomotives, and I have never heard of it done before on the prototype or models. I think the same would hold for any AB units for similar reasons. I don't have an AB set out to see how long they are. Less tracks off the turntable would be good to eliminate the curved ones. The 4-way switch for the yard saves space, but then you would need a runaround track on each side of the yard. I have 4% grades on my layout, and they are working alright on my short trains. I'm sure you would like to run longer trains than I can. I setup a temporary track and tried it at different grades with each of my engines pulling cars to see what would work. Remember that it takes a little more pulling power on grades than straightaways.

Hi Mark,

Loco & tender for post war Berkshire 736 is about 21" so no worries there for now. Illinois Central Diesel AB unit is about 28" And I can imagine the NYC K-Line would be slightly longer, about 33" for A/B units. And I now see that the 4-way switch is an issue with runaround tracks. Glad to hear your 4% grades are ok I was shooting for 3.5% max grade and will do the experiment you did with actual trains pulling a consist up that grade and around curves. Great Advise Mark, Thanks!

@DoubleDAZ posted:John, I meant no offense. I’ve been assuming you’ve just been filling the space with track, but at some point you have to come back down to earth and work with something more realistic and, more importantly, something that will fit. 🤪 You now know a 4-stall Altoona roundhouse with 34” turntable will fit, so it’s time to build on that to see if a useful yard can be designed around it. Personally, I suspect you don’t need anything larger than the smaller turntables that are in the SCARM libraries. So many want to use the biggest turntable and biggest curves that they miss out on design possibilities smaller curves would allow.

Anyway, when it comes to fit, yes, the tender has to be included, though technically I suppose an engine alone could be pushed/pulled by another engine. Think about it though. If you push an engine onto the turntable, how will you get it into the roundhouse or onto a whisker track? A-B units would be the same, but don’t know if A-B units are even turned on a turntable. Many, if not most, yards have engine houses, not turntables and roundhouses. Also, there’s nothing wrong with having a turntable just to turn engines, it doesn’t have to include a roundhouse.

The yard is another story. You can have a storage yard, like what you have, to store multiple trains ready to be run or you can try to fit in a working yard where a switcher moves cars around to configure different trains. Obviously, a working yard requires more than just storage tracks and I don’t know that you have the space for both a turntable/roundhouse and a working yard, at least not where they are now.

Hi Dave, no offense taken, actually the honest assessment is greatly appreciated. A working yard, rather than a storage yard is preferred. And if it would work a smaller turntable someplace. Looking at some of the layouts, it is becoming more apparent less track with more purposeful/useful track is much better for a working railroad. I was thinking maybe only one main line might lend itself to an overall better design.

please add your thoughts

Many thanks

john

John, I’m a big fan of dual mainlines, mostly because you can run trains in opposite directions and simulate having turned engines without actually doing so. I’m also a big fan of over/under sections, elevation chamfers, etc. I have no affiliation with railroading, so I have no idea how things are done in real life. I just know what I like to see as we travel around the country and that’s trains going every which way. We see a lot of trains along I-10 through New Mexico and we especially enjoy seeing them pass each other out in the wide open spaces. I was hoping by now we’d have some additional eyes offering ideas, so I’m going to have to give this some more thought as I get time.

Thanks for your candid reply

John, I'm like Dave, I wish more folks would comment. Maybe it i worth a shot if you edit the topic title to something different than "Newbie Planning". My original topic was called "new-o-gauge-layout-in-under-144-square-feet". I'm not suggesting any name, but maybe a new title will catch more folks eyes. Just a thought.

Hi Mark,

Yes it is time for a new topic on layout planning and operation.

How to get 10 pounds of layout in a five pound area!

I'll think about it tomorrow when I'm more coherent.

Thanks John

Yes, I just edited the topic title to keep the history about what was already discussed, but you could start a new topic. Either way.

Hi Mark,

As you see I took your suggestion on the edit title route. Now with some better understanding of yards and operations, I'll have a different perspective on track placement and utilization.

Thanks for the support

@DoubleDAZ posted:John, I’m a big fan of dual mainlines, mostly because you can run trains in opposite directions and simulate having turned engines without actually doing so. I’m also a big fan of over/under sections, elevation chamfers, etc. I have no affiliation with railroading, so I have no idea how things are done in real life. I just know what I like to see as we travel around the country and that’s trains going every which way. We see a lot of trains along I-10 through New Mexico and we especially enjoy seeing them pass each other out in the wide open spaces. I was hoping by now we’d have some additional eyes offering ideas, so I’m going to have to give this some more thought as I get time.

Sounds like we are in the same mind set with over/under sections, two close main lines for opposite directions. Having said that it is also important to have some realistic operations and purpose with industries and towns. My only affiliation with railroading, was my Dad worked for the Pullman company out of NYC and I would visit Sunnyside yards in Queens NY. That and getting Lionel trains for xmas. At one point I thought about putting in towns and then industries and building a railroad to meet the needs of the industries and towns. Which is the way it naturally evolved when the country went from wagon trains to steam trains. With the space I have (which I am grateful to have) the layout should have some purpose and lots of fun with a bit of nostalgia thrown in for good measure. My trains have only been put up around the Christmas tree these past couple of years since we adopted our daughter. So that is about the extent of my knowledge and wants with building a model railroad.

And you’ve just hit on my Achilles Heel, adding realistic operations. It’s one thing to design a general flow around the room, but quite different adding spurs, buildings, etc., to serve as destinations. In Mark’s case, he had the basic operation in mind for his point to point, so all I did was help connect the 2 points with tracks that would fit. He started with 2 turntables that became reversing loops and eventually were replaced with an around the room design due to changes to the available space. Throughout all the changes, he kept the basic operation intact, city in the lower right up to an industry in the upper right.

In your case, we’re laying down an around the room flow and trying to come up with a reason for it to exist. You’ve got space before the bridge in the lower right for an industry of some sort. You’ve got room past the bridge for a mall towns but the elevation change going up will have an impact. You have room in the elevated upper left for another industry, like timber or mining. Then, of course, there’s the peninsula area where you’d like a turntable. There are others areas for spurs with businesses to be serviced or the passing sidings you currently have. I’m terrible at coming up with a theme because I just like to run trains, not service spurs.

Hi Dave,

Looks like having some areas designated for towns and industries and then trying to get a flow of main lines and servicing spurs has some merit. The elevation of the two main lines makes some of the design work interesting. I have trouble with having scarm have a turnout on a grade. So then grades start or end at turnouts unless there is enough track to get to the desired elevation.

Thought about moving turntable to lower right by bridge. That will eat up industry area. Looking for a coaling operation to model and using some gantry crane for maybe steel. Then a town or two with roads etc. Using the existing baseboard I'll layout some industries and designate town areas to see what can be done. I also have trouble picturing what is on scarm with how it translates to tabletop. I check the 3D drawing in scarm, but I have a block on putting in other objects once track is down.

Again Thanks for the help and support!

SCARM doesn't allow turnouts on grades, so you have to use a workaround. Obviously, the blue track (base) is on a flat surface at 0" elevation with the intent to raise the right end to 4". To do this, you need to experiment a little. I don't know if this will help, but let me know if you can't follow it and I'll try again.

The first step is to remove the turnout, fill the empty space, then create the grade (sample 2). Note that the grade is 2.9%.

When you compare sample 2 to the base, you can see that the turnout begins the grade at about the 1" point. So, the turnout (green) gets set to 1" on all 3 points (sample 3). Then you create the grades (purple) on both ends of the turnout. Note the grade TO the turnout becomes 2.7% while the grades on the other end are 3.4% and 3.5%. Note too that the first grade ends at 1" and the other 2 grades then begin at 1" and end at 4", but the slope of the grade is more than the original 2.9%.

If you plan to set the turnout on the grade, you can simulate that by deleting the turnout and again filling it in (sample 4). You can see in sample 2, you can see that the turnout would end at the 1.5" point. So you then set the grade of the straight through section from 0' to 4" and then set the grade for the turnout section from 1.5" to 4". Note that the grades for both are 2.9%.

@DoubleDAZ posted:SCARM doesn't allow turnouts on grades, so you have to use a workaround. Obviously, the blue track (base) is on a flat surface at 0" elevation with the intent to raise the right end to 4". To do this, you need to experiment a little. I don't know if this will help, but let me know if you can't follow it and I'll try again.

The first step is to remove the turnout, fill the empty space, then create the grade (sample 2). Note that the grade is 2.9%.

When you compare sample 2 to the base, you can see that the turnout begins the grade at about the 1" point. So, the turnout (green) gets set to 1" on all 3 points (sample 3). Then you create the grades (purple) on both ends of the turnout. Note the grade TO the turnout becomes 2.7% while the grades on the other end are 3.4% and 3.5%. Note too that the first grade ends at 1" and the other 2 grades then begin at 1" and end at 4", but the slope of the grade is more than the original 2.9%.

If you plan to set the turnout on the grade, you can simulate that by deleting the turnout and again filling it in (sample 4). You can see in sample 2, you can see that the turnout would end at the 1.5" point. So you then set the grade of the straight through section from 0' to 4" and then set the grade for the turnout section from 1.5" to 4". Note that the grades for both are 2.9%.

Neat trick Dave! I think I follow and will try on scarm to verify I understand the proceedure.

Thanks John

Dave, we spent so much time on all the versions of my layout plan, you remembered very well.

John, The lower town Dave mentioned (Parsons-Hendricks, WV) had logging and a tannery. Today there is a Kingsford charcoal plant. Thomas WV is at the top of the mountain and was basically a coal marshalling yard. Today there is Mount Storm Power Station where I worked in the '90s that took coal right from the mine until the correct grade of coal was mined out, now they bring it in from Cumberland the opposite direction from my section. Today the railroad is a rails to trails up the mountain from Parsons. It is ironic, that a forum member suggested this very railroad as a prototype the first few days after I started my topic, and I had already planned an HO layout of the same area I was familiar with back in the late '90-'00s.

Of course as Dave mentioned I had to do a lot of compression and trimming to fit it in an 11x11 room, but it is working out.

I like seeing your roundhouse and turntable on the peninsula by the double bridge. The only trouble is the yard is on the other side of the two mainlines. I know you are just trying to get the feel of doing some more advanced things with SCARM, but every variation you has the potential of making something click and lead to a great idea. I'm with Dave, Ilike the two routes and you can have trains going each way.

When are you hoping to start building benchwork? It won't be long now that the leaves will be down and we will have them cleaned up as best we can for the winter. (Dave doesn't get the privilege of raking leaves and shoveling snow any more.) It's a shame! ![]()

Mark,

I deal with bags of leaves every weekend here. We have 2 large Ficus trees that shed leaves all year long plus 2 adult fruit trees with 3 more young ones growing and a Texas Lilac. Just today I ran 5 bags, 33 gallons each, over to my brother-in-law’s where he mulches them in his rather large flower beds. Two weeks ago it was 4 bags (39 gallons) and 3 bags (33 gallons). It tapers off over the winter where I only bag once a month or so and we’re having the trees pruned on October 20, which will help. Pruning is quite expensive, but it’s a cost I’m willing to bear. Had I known this beforehand though, I probably wouldn’t have planted the trees.

It’s true enough though that I no longer deal with snow and there are only a few days where I deal with a frosted windshield. That I don’t miss. 😝

John,

When it comes to model railroad "operations," there is a lot of existing information out there. For starters, there is an NMRA Special Interest Group for Layout Design (LDSIG). I believe they have a Facebook page and operate under a group.io format as well. I signed up to get their e-mails from group.io (which is a Google operation, I believe) and the information they discuss can be quite useful. Their focus is on layout design for better operations.

There have also been numerous articles and authors that have discussed this topic, starting with Frank Ellison in the 1950s(?) (a 6 part series in Model Railroader called "The Art of Model Railroading") and continuing today through people like Tony Koester. There are also quite a few books on the subject, but the one most often recommended is "Planning Your Model Railroad for Realistic Operation" which is a Kalmbach publication, I believe. "Operating" a model railroad can be tons of fun if you design your plan well, but as I view it, your current plan is really only good for "looping" with the added ability of changing the trains / engines that run the loops.

To operate, you have to get down to the nitty-gritty of what industries you want to model or what locations (whether towns or areas of the country) you want to model. Some people prefer to model large industries like steel mills, coal mines, refineries, or automobile manufacturers. Others prefer to model smaller industries built within or near towns (including ports), while some prefer to model unit trains hauling their dedicated cargoes between large yards. Finally, there are those that like to model passenger operations (either city-to-city or commuters) and those that like to model short-lines that only serve a few customers from an interchange with a Class 1 railroad.

Whatever you choose, it might also help if you develop a "back story" for why your railroad exists, if it is fictional. If not fictional, use location names that at least sound like they might have been found along the railroad you model. E,g., you would probably not find Sonora along the Pennsylvania RR.

As you can see, the "operation" possibilities are quite open, and anyone wanting to help you must know your limitations and choices, something the planners call "givens and druthers." One thing I've learned from the LDSIG and other readings is the idea of LDE, Layout Design Elements. You get ideas (including from other people's layouts) from anywhere about what you like to have in your layout (a port, a steel mill, one or more small towns, an interchange, etc.), then you draft a scaled down version that meets your needs and will fit in your layout space without overpowering it. Then you try and fit as many of these LDEs as you can into your layout, connecting them all in some logical way (or any way that makes you happy, as long as it makes operating sense).

You have to be the one to choose and design your LDEs. Once those are done, friendly people here will offer suggestions for improvement and might even offer suggestions for how to squeeze them into your space in a logical manner.

Good luck,

Chuck

@Mark Boyce posted:Dave, we spent so much time on all the versions of my layout plan, you remembered very well.

John, The lower town Dave mentioned (Parsons-Hendricks, WV) had logging and a tannery. Today there is a Kingsford charcoal plant. Thomas WV is at the top of the mountain and was basically a coal marshalling yard. Today there is Mount Storm Power Station where I worked in the '90s that took coal right from the mine until the correct grade of coal was mined out, now they bring it in from Cumberland the opposite direction from my section. Today the railroad is a rails to trails up the mountain from Parsons. It is ironic, that a forum member suggested this very railroad as a prototype the first few days after I started my topic, and I had already planned an HO layout of the same area I was familiar with back in the late '90-'00s.

Of course as Dave mentioned I had to do a lot of compression and trimming to fit it in an 11x11 room, but it is working out.

I like seeing your roundhouse and turntable on the peninsula by the double bridge. The only trouble is the yard is on the other side of the two mainlines. I know you are just trying to get the feel of doing some more advanced things with SCARM, but every variation you has the potential of making something click and lead to a great idea. I'm with Dave, Ilike the two routes and you can have trains going each way.

When are you hoping to start building benchwork? It won't be long now that the leaves will be down and we will have them cleaned up as best we can for the winter. (Dave doesn't get the privilege of raking leaves and shoveling snow any more.) It's a shame!

Hi Mark,

Your layout is fantastic and looks like it will provide endless enjoyment. Great job on adapting and putting in so much in your space.

Turntable was "thrown" there to get out of the way and no rhyme or reason to it, however it is growing on me. And two main lines will say in for the reasons you and Dave stated, looks cool!

As far as bench work goes, solid or at least semi-solid plans need to be on paper first. One more sticking point is the double track bridge that will be a hinged lift for access to middle. The issue is both main lines are at same elevation and then it is a long grade to go for over/under main line crossings. Doesn't lend it self for breaking out spurs or siding at different elevations. I would love to get bench work started before Dec.

How are you doing on your layout? Sounds like leaves have taken over! A friend of mine back in conn. Was asked where he wanted to retire to? He said he would put his snowblower in the back of his truck and drive south until some one asked him what the contraption was in his pick up!

@PRR1950 posted:John,

When it comes to model railroad "operations," there is a lot of existing information out there. For starters, there is an NMRA Special Interest Group for Layout Design (LDSIG). I believe they have a Facebook page and operate under a group.io format as well. I signed up to get their e-mails from group.io (which is a Google operation, I believe) and the information they discuss can be quite useful. Their focus is on layout design for better operations.

There have also been numerous articles and authors that have discussed this topic, starting with Frank Ellison in the 1950s(?) (a 6 part series in Model Railroader called "The Art of Model Railroading") and continuing today through people like Tony Koester. There are also quite a few books on the subject, but the one most often recommended is "Planning Your Model Railroad for Realistic Operation" which is a Kalmbach publication, I believe. "Operating" a model railroad can be tons of fun if you design your plan well, but as I view it, your current plan is really only good for "looping" with the added ability of changing the trains / engines that run the loops.

To operate, you have to get down to the nitty-gritty of what industries you want to model or what locations (whether towns or areas of the country) you want to model. Some people prefer to model large industries like steel mills, coal mines, refineries, or automobile manufacturers. Others prefer to model smaller industries built within or near towns (including ports), while some prefer to model unit trains hauling their dedicated cargoes between large yards. Finally, there are those that like to model passenger operations (either city-to-city or commuters) and those that like to model short-lines that only serve a few customers from an interchange with a Class 1 railroad.

Whatever you choose, it might also help if you develop a "back story" for why your railroad exists, if it is fictional. If not fictional, use location names that at least sound like they might have been found along the railroad you model. E,g., you would probably not find Sonora along the Pennsylvania RR.

As you can see, the "operation" possibilities are quite open, and anyone wanting to help you must know your limitations and choices, something the planners call "givens and druthers." One thing I've learned from the LDSIG and other readings is the idea of LDE, Layout Design Elements. You get ideas (including from other people's layouts) from anywhere about what you like to have in your layout (a port, a steel mill, one or more small towns, an interchange, etc.), then you draft a scaled down version that meets your needs and will fit in your layout space without overpowering it. Then you try and fit as many of these LDEs as you can into your layout, connecting them all in some logical way (or any way that makes you happy, as long as it makes operating sense).

You have to be the one to choose and design your LDEs. Once those are done, friendly people here will offer suggestions for improvement and might even offer suggestions for how to squeeze them into your space in a logical manner.

Good luck,

Chuck

Hello Chuck,

Thanks for the referrals on Ldsig, NMRA site has been confusing for me, however I'll try again. As for reading, I'm just starting a operations layout book by Armstrong and have just gotten another by Tony Koester. Hoping to garner railroad knowledge for sure which will help clear the ton of mud I seem to be in. Also great suggestion of a back story for sorting out what the railroad does to earn its keep. That will force me to pen givens and druthers.

Thanks a ton for all the help

John

John, My layout building is very slow right now. That is why I haven't posted anything on my own topic or the 'What did you do on your layout' topic. I did figure out a place to add another rather long spur on the lower level, cut in a switch from the main line, and added a bit of roadbed. This has all been done in very short spurts over the last few weeks.

Since it cooled down from the unusually hot summer weather, I have been trying to finish up everything outside I didn't get done last summer with my knee surgery looming and this years things. I have maybe a couple hours more painting to do and an afternoon of work to fix the end of a cracked drainage pipe. Since we still aren't getting much rain, I have only been mowing about once a month since June, so I should wrap those things up before the leaves are falling in ernest. Actually, with the dry weather, we have been seeing a few leaves falling all through the summer. I have never seen that. Maybe I was was wrong, and we have more like Dave's weather here around Butler. Looking at the radar, almost every time there was rain coming in from Ohio, it went north of us up your way. The one storm we got about a month ago broke limbs off one of our trees and the tree trimmers have cleaned that all up. Maybe I won't have as many to clean up this year!

John. It looks like you understood my explanation about placing the turnout on a grade in SCARM. Just be aware that during construction you don't want to start/end a grade at a turnout. As Mark will tell you, it's not easy to ease into or out of a grade to get a smooth transition and a turnout just complicates things. The main point of the exercise in SCARM though is just to see how things will fit, adjustments are always needed when actually constructing grades to get things to work smoothly.

Anyway, I took the liberty of further color coding the grades. This allows you to select them simply by double-clicking to check or change the grade. Color coding also lets you readily see where grades begin/end. I noticed the grade down to the bridge wasn't set and the yard area was elevated to 7", so I fixed those. Further, I know you're just playing around with things, but I'm curious how you think you'd use the long spur that goes just beneath the yard and the lone spur coming off the yard. I'm hesitant to fiddle with the yard design until I get a better feel for your thoughts.

Hi Dave, Again thanks for the free scarm lesson. As for what is on layout now, it is just throwing ideas around and elevations went out the window so to speak. Am reading some good books on layout and operational design. Some of how I was thinking or picturing spurs and sidings we’re totally backwards. I will say two main lines is something to strive to have on layout

Again many Thanks

John

Based on info in previous posts re operations and NMRA resources (all very good info, BTW) and responses, I'm getting the impression that you may be trying to do too much too soon. This is not meant as a criticism; I suffer from this syndrome myself.

It's incredibly difficult to design and build the "perfect" layout (if such a thing exists), especially if you haven't built one recently. "Operations" (in NMRA parlance) can be interesting for some folks, and stressful and tedious for others. Before going all-in on operations, I suggest attending an ops session in your area to see if that's your cup of tea. You might love it, or you might learn that you'd rather be a loop runner - although some rivet counters might disagree, IMO there's no shame in that.

The Black Diamond Railway series of DVDs might be worth watching - covers the entire process of building a high quality 3-rail layout from start to finish.

Good luck on the journey.

John, Mallard has a good point. I know after attending an operating session on a large HO layout in Pittsburgh probably 20 years ago that I don't like operations of switching cars in and out going from one industry to another along the mainline. On the other hand, just rolling trains around endlessly on one or any number of loops is not interesting to me either. I do not know how much I will like this layout I'm building, but it is kind of in between those two extremes.

I have the Black Diamond Railway set of DVDs Mallard referred to if you would like to borrow them.

@Mallard4468 posted:Based on info in previous posts re operations and NMRA resources (all very good info, BTW) and responses, I'm getting the impression that you may be trying to do too much too soon. This is not meant as a criticism; I suffer from this syndrome myself.

It's incredibly difficult to design and build the "perfect" layout (if such a thing exists), especially if you haven't built one recently. "Operations" (in NMRA parlance) can be interesting for some folks, and stressful and tedious for others. Before going all-in on operations, I suggest attending an ops session in your area to see if that's your cup of tea. You might love it, or you might learn that you'd rather be a loop runner - although some rivet counters might disagree, IMO there's no shame in that.

The Black Diamond Railway series of DVDs might be worth watching - covers the entire process of building a high quality 3-rail layout from start to finish.

Good luck on the journey.

All good info! Although I cannot predict where my interest will take me, the fact I have purchased over the years, two coal loaders, icing station and two gantry cranes show interest in industries. Being able to have those industries integrated properly with a railroad in an intelligent efficient manner is a given. To run operations with time tables and schedules may be too much for my interest now. That may change in the future, but for now those are my general tendencies.

Doing too much too soon hits the nail on the head! Learning benchwork, backdrop painting, New electronics for trains (New for 1950's) getting back into trains after 50 years is a lot of catching up!

Thanks for your help, all is appreciated.

John

@Mark Boyce posted:John, Mallard has a good point. I know after attending an operating session on a large HO layout in Pittsburgh probably 20 years ago that I don't like operations of switching cars in and out going from one industry to another along the mainline. On the other hand, just rolling trains around endlessly on one or any number of loops is not interesting to me either. I do not know how much I will like this layout I'm building, but it is kind of in between those two extremes.

I have the Black Diamond Railway set of DVDs Mallard referred to if you would like to borrow them.

Mark, sounds like we have same general interest in railroading. Would love to borrow your dvd 's The strict operations for me is too much at this point. Have you figured out your dual height bridges?

John, I watched some YouTube videos on similar projects. It doesn't matter what scale they are to get the concept and construction. So far they were way too elaborate for my situation since they were lifting up or swinging up a whole section with scenery. One of those in England had good ideas on the electrical interlocks to power tracks when the bridge is down and stop power before the bridge when in the up position. I think just making lift up bridges with no scenery would be best for both yours and my application. The more mass you want to lift, the more sturdy you have to make the lift section and where it hinges to the stationary layout to keep it from skewing. My thought so far is to make two bridges that operate separately. In your case of course you can use one double track bridge.

I'll send a private message later to discuss getting the DVDs to you. I think sharing ideas about each of our builds here benefits both of us, and could help getting others involved in the discussion. Discussing logistics of getting together works better on private message.

Hi Mark,

I can see the wisdom in two bridges without scenery for weight and complexity. The problem my twin track bridge poses has both lines at same elevation which using 3% grade creates a long run before they can cross over/under. I was wondering if a second single track bridge at a lower elevation would open up more possibilities without making it too cumbersome to get in and out. Are you looking at a swing up or swing down or maybe one of each? It seems to be better to swing up if overhead clearance allows. Setting the bridge down on a support bracket rather than somehow locking in a swing down bridge in the running position would afford increased stability. If you have overhead room, having your two bridges tied together at the end that rises might be an option. Both swing up and down together, using some aluminum channel to tie them together. With a couple of locating pins or other alignment fixtures the running position could be made secure and precise enough to allow smooth rail transitions. Just a thought.

I hadn't paid attention that your bridge is on the grade. I ignored Dave's fine color coding. ![]() You definitely would have more flexibility if you used separate bridges, but then you would have to fuss with two lift-ups. Both of my tracks are level at the bridge site. As I worked my way around the room with the benchwork, I ended up with the second end 1/2 inch lower than the other. By the time I found it, I had put shelves in underneath and loaded them to make room to work. I had to jack up the left end and worked out the problem. For some reason, I like level bridges, though we see them at all angles in this part of the country all the time.

You definitely would have more flexibility if you used separate bridges, but then you would have to fuss with two lift-ups. Both of my tracks are level at the bridge site. As I worked my way around the room with the benchwork, I ended up with the second end 1/2 inch lower than the other. By the time I found it, I had put shelves in underneath and loaded them to make room to work. I had to jack up the left end and worked out the problem. For some reason, I like level bridges, though we see them at all angles in this part of the country all the time.

I was planning on making both of mine lift-ups for the reasons you state. There is plenty of head room. I don't think I am up to trying to gang two bridges to lift up together when they are separated by 6 1/2 vertical inches. Here are photographs of the temporary lift out I made, which shows the problems of having the two tracks at different levels. I just connect alligator clips to the wires from the rails. I just put screws into the sides of the table to align it. It is awkward to put in place as the alignment never quite works out, but the intent was a quick build until I can come up with something more substantial and permanent. Trains do go across both tracks fine.